When your commercial ice cream machine breaks down, start by checking if the issue is with the refrigeration or the motor. First, verify the temperature settings and listen for unusual noises from the compressor. Make certain electrical connections and safety switches are secure. Clean condenser coils and inspect for refrigerant leaks. For motor problems, confirm power supply, listen for strange sounds, and look for jams or burnt smells. If these steps don’t fix it, there’s more to explore to get your machine running again.

Key Takeaways

- Check if the machine is properly plugged in and circuit breakers are not tripped.

- Verify temperature settings are correct according to manufacturer guidelines.

- Listen for unusual noises from the compressor, indicating possible failure.

- Inspect electrical connections and safety switches for damage or tripping.

- Ensure the condenser coils are clean to maintain proper refrigeration.

If your commercial ice cream machine isn’t working properly, troubleshooting can save you time and minimize downtime. The first step is to identify whether the issue stems from refrigeration problems or motor issues. Both are common causes of machine failures and can often be resolved with some straightforward checks. Recognizing the difference will help you diagnose the problem quickly and get your machine back in operation faster.

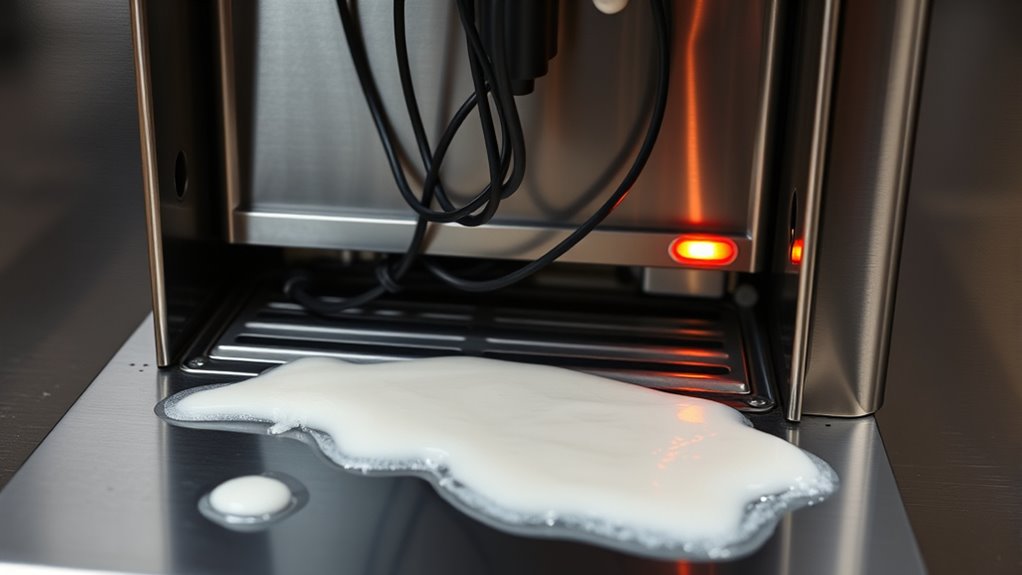

Start by inspecting the refrigeration system. If your ice cream isn’t freezing properly or the machine isn’t maintaining the correct temperature, refrigeration issues are likely to be blame. Check the temperature settings; sometimes, they get accidentally adjusted, so ensure they’re set according to the manufacturer’s recommendations. Also, listen for unusual noises or sounds coming from the compressor, which can indicate it’s struggling or failing. If the compressor isn’t running, it could be due to a tripped circuit breaker or a blown fuse, so verify your electrical connections first. Dirty or clogged condenser coils can also hinder heat exchange, leading to refrigeration problems. Regularly cleaning these coils helps maintain proper cooling. If the refrigerant level is low or there’s a leak, that’s a more complex issue typically requiring a professional repair. But initially, a simple visual inspection can help you rule out obvious issues. Understanding airless paint sprayer components can also aid in troubleshooting electrical or mechanical issues more effectively.

Next, focus on potential motor problems. The motor powers the dasher or agitator, which is essential for churning the ice cream mixture. If the motor isn’t running, your machine won’t produce ice cream, even if the refrigeration system is functioning correctly. First, check whether the motor is getting power. Sometimes, a loose or disconnected wire causes the motor to stop working. Look for any signs of damage or burnt smell, which might indicate overheating or electrical failure. If the motor hums but doesn’t turn, it could be jammed or stuck, so try to manually rotate the shaft gently to see if it moves freely. Over time, motor bearings can wear out, leading to noisy operation or failure to start. In such cases, replacing the motor or its components may be necessary. Also, ensure safety switches or thermal overload protectors haven’t tripped, as these can prevent the motor from running to avoid damage. Properly maintaining electrical connections can prevent many common motor issues and prolong the life of your equipment. Additionally, consulting manufacturer guidelines can provide specific troubleshooting steps tailored to your machine model. Regular inspections of refrigeration system components can help prevent unexpected breakdowns and extend the lifespan of your machine.

Frequently Asked Questions

How Often Should I Perform Maintenance on My Ice Cream Machine?

You should follow a regular maintenance schedule to keep your ice cream machine running smoothly. Typically, you need to clean your machine after every use or at least daily, depending on usage. Regular cleaning frequency prevents buildup and assures quality. Additionally, perform scheduled maintenance, like inspecting parts and lubricating as recommended by the manufacturer, usually weekly or monthly. Staying consistent with cleaning and maintenance will extend your machine’s lifespan and prevent breakdowns.

Can I Fix the Machine Myself or Should I Call a Professional?

You might think DIY repairs are simple, but many ice cream machine issues are complex. Investigate whether your problem is something you can handle safely or if it requires professional assistance. Attempting repairs without proper knowledge can cause further damage or safety hazards. When in doubt, it’s smarter to call a professional. They have the necessary tools and expertise to fix your machine correctly, saving you time and avoiding costly mistakes.

What Are Common Signs Indicating My Machine Needs Repair?

You notice your machine’s ice cream isn’t as smooth or creamy as usual, which signals it might need repair. Unusual noises during operation, like grinding or squealing, also indicate a problem. If the consistency suddenly worsens or strange sounds persist, it’s a clear sign you should check the machine or call in a professional. Addressing these signs early helps prevent further damage and guarantees your ice cream stays top quality.

Is It Safe to Use a Machine With Electrical Issues?

When your machine shows electrical issues, it’s wise to prioritize electrical safety. Using it could risk electrical shock or further damage, making machine repair more complicated. Instead, unplug the machine and consult a professional to evaluate the problem. Ensuring proper repairs safeguards your safety and keeps your equipment in top shape. Never compromise on electrical safety—address issues promptly to prevent costly accidents and maintain smooth operations.

How Can I Prevent Future Breakdowns of My Ice Cream Machine?

To prevent future breakdowns of your ice cream machine, focus on routine preventive maintenance and regular equipment calibration. Clean the machine thoroughly after each use, check electrical components regularly, and keep parts lubricated as recommended by the manufacturer. Scheduling timely inspections and calibrations ensures peak performance and reduces the risk of unexpected failures. Staying proactive with maintenance helps extend your machine’s lifespan and keeps your operations running smoothly.

Conclusion

When your ice cream machine stalls, think of it as a stubborn mule refusing to move. Before calling for help, try these simple fixes—they might just be the key to reviving your machine’s chilly magic. Remember, patience and a little troubleshooting can turn a frosty nightmare into a smooth-sailing solution. Keep calm, stay cool, and soon you’ll have your ice cream flowing like a frozen river, ready to delight your customers once again.