Built-in vacuum systems work by connecting a powerful motor and a network of airtight PVC pipes throughout your home. When you turn on the inlet valve and use a hose, the motor creates strong suction that pulls dirt and dust into a central collection container. The system uses filters or cyclonic separation to keep dirt out of the air, which improves indoor air quality. To discover how to optimize performance and maintenance, keep exploring these key components.

Key Takeaways

- Central vacuums house a motor, dirt container, and filters, connected to inlet valves via airtight PVC piping.

- Suction is generated by spinning turbines at high RPM, creating a pressure difference that pulls debris into the system.

- Proper piping layout and inlet valve placement ensure efficient airflow and easy access for cleaning.

- Cyclonic separation and filters trap dust, with regular maintenance needed for optimal performance and indoor air quality.

- Dirt and pollutants are often vented outside, improving indoor air quality and reducing allergens.

Components of a Central Vacuum System

A central vacuum system consists of several key components that work together to provide efficient cleaning. The central vacuum unit acts as the system’s heart, housing essential parts like the dirt container, where debris collects, and a filter or separator that keeps dirt and air separate. In cyclonic systems, a cyclone separator spins dust away from the air, while filtered systems use a media to trap particles. PVC pipes connect the unit to inlet valves installed throughout your home’s walls, carrying debris from hoses to the central unit. These pipes must be airtight for optimal suction, and fittings ensure a secure connection. Exhaust vents or mufflers are added to reduce noise and expel air outside, maintaining a quieter, cleaner environment. Proper installation and maintenance are crucial to ensure the system functions effectively over time. Additionally, airflow dynamics play a significant role in maintaining consistent suction and overall system performance. Regular checks of system components can help prevent blockages and ensure longevity of your vacuum system.

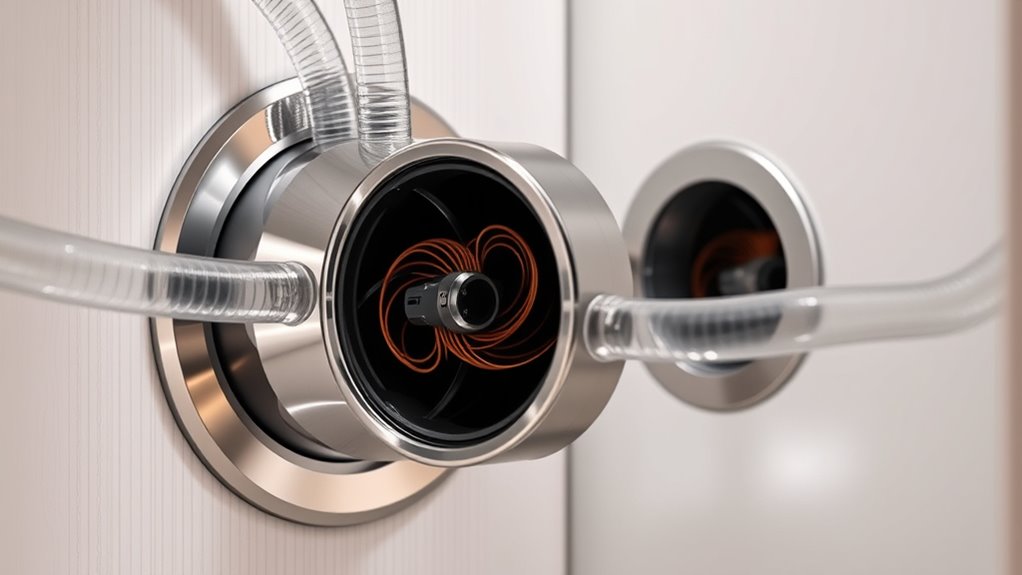

How the Motor Powers Suction

The motor drives the central vacuum system by spinning turbine-like components at thousands of RPM, creating a pressure difference that pulls air and debris into the pipes. This suction power depends on four key factors:

- Motor type and cooling method – flow-through, peripheral bypass, or tangential bypass, affecting durability and noise. Cooling methods play a vital role in maintaining motor performance during extended use.

- Suction strength – measured in inches of waterlift, indicating how well debris is lifted.

- Airflow (CFM) – the volume of air moved, essential for covering large areas.

- Motor configuration – series boosts suction pressure, while parallel increases airflow, tailored to cleaning needs.

Together, these elements generate the strong, efficient suction needed for effective cleaning and debris removal. Additionally, the design of the motor influences its ability to operate continuously without overheating, ensuring consistent performance during prolonged cleaning sessions. Proper motor design also impacts the durability and overall lifespan of the central vacuum system, making it a critical consideration when selecting a unit.

Role of the Piping Network in System Efficiency

Optimizing the piping network is vital for maintaining consistent suction and overall system efficiency. You should design the layout to minimize pipe length and sharp bends that cause airflow loss. A well-planned, linear network helps balance suction across all inlets, ensuring reliable performance. When routing pipes, consider your building’s layout, size, and obstacles to optimize placement. Reducing sharp turns improves airflow by lowering pressure drops, which keeps suction strong. Proper inlet placement is also essential; positioning them to maximize coverage with minimal piping reduces hose length and enhances user convenience. Using appropriate pipe diameters and quality materials like PVC or metal prevents turbulence, leaks, and clogs. Incorporating safety features such as slopes and traps guarantees liquids don’t stagnate, boosting system longevity and efficiency. Additionally, understanding the importance of airflow dynamics can help prevent pressure drops and maintain optimal suction throughout the system. Paying attention to nutrient retention during installation can also prolong the system’s effective operation by preventing blockages and buildup.

Types of Dirt Separation and Filtration

You need to understand the different dirt separation and filtration methods used in built-in vacuum systems. Cyclonic separation uses centrifugal force to remove debris without filters, while filter and bag systems trap dust with various materials. Knowing the strengths and limitations of each helps you choose the right system for your cleaning needs. Additionally, advancements in technology integration are enhancing the efficiency and ease of maintenance of modern central vacuum units. Modern systems also incorporate filter materials that improve dust capture and reduce allergens in the home environment.

Cyclonic Separation Method

Cyclonic separation is a key method used in central vacuum systems to remove dust and debris from the airflow without relying on traditional filters. It uses centrifugal force to toss particles outward against the cyclone walls, where gravity causes them to fall into a collection chamber. The conical shape boosts air speed, increasing separation efficiency. Here are four key points:

- Dust-laden air enters tangentially, creating a vortex that separates particles by inertia.

- Particulates lose momentum and gravity pulls them into a collection chamber.

- Different cyclone types include single, multiple, and secondary-air-flow separators for various needs.

- Cyclonic separation reduces dust reaching filters, prolonging system life and maintaining strong suction.

Filter and Bag Systems

Filter and bag systems are essential components of built-in vacuum setups, responsible for trapping dust and debris after they’re separated from the airflow. HEPA filters are highly effective at capturing small particles, allergens, and dust, making them ideal if allergies are a concern. Foam filters are more economical but less efficient, often used with cyclonic separation for added filtration. Some systems feature maintenance-free filters that clean themselves, reducing upkeep. Bagged systems provide a hygienic way to contain dirt, with disposable bags that minimize exposure to allergens. Bagless models use collection bins, offering easier maintenance but may require more frequent emptying. Hybrid systems combine both options, giving you flexibility based on your cleaning needs. Proper filter maintenance, including cleaning or replacement, guarantees the best system performance. Additionally, understanding juice detox methods can support overall health and energy levels, which can enhance your cleaning routine and general well-being.

Installation and Design Considerations

When planning your vacuum system, focus on ideal pipe routing to reduce long runs and sharp bends, which helps maintain strong suction. Position inlet valves in accessible, unobstructed wall areas, aligning them with power outlets for convenience. Carefully select the power unit location to ensure easy access, noise control, and proper connection to your piping and electrical supply. Additionally, considering European cloud innovation in your planning can inspire more sustainable and secure system design choices. To further optimize performance, consider the system layout to ensure efficient airflow and maintenance access.

Optimal Pipe Routing

Ideal pipe routing is essential for maximizing the efficiency of your built-in vacuum system. Proper routing ensures smooth airflow, balanced suction, and easy maintenance. Focus on minimizing pipe length and sharp turns, which decrease airflow. Choose a linear, centralized design to distribute suction evenly. Before installation, plan routes carefully to avoid hidden wiring or plumbing obstructions. Run tubing straight and level in both directions for ideal airflow. Avoid 4-way cross fittings by staggering branch lines from the main trunk. Additionally, use smooth internal piping like Schedule 40 PVC or copper, and employ 45-degree elbows instead of sharp turns. Incorporate clean-out ports every 40-50 feet or at 90-degree changes for maintenance access. Proper routing minimizes airflow resistance, ensuring your system works efficiently and reliably. Efficient pipe routing is also supported by modern technology that helps visualize airflow paths during planning.

Inlet Valve Placement

Strategic placement of inlet valves is essential for ensuring extensive coverage and ease of use in your built-in vacuum system. Position valves in central locations like hallways, near doors, or staircases to maximize accessibility. Avoid hiding valves behind furniture or doors to prevent access issues. Install them at a height matching electrical outlets for convenience, but feel free to adjust for user preference. Use a 30-foot hose or string to verify reachability across all areas. Overlapping zones from multiple inlets boost cleaning efficiency. Proper zone planning ensures that all areas are effectively covered without redundancy or missed spots. Considering the layout of your home can also help optimize valve placement for maximum coverage and efficiency.

Inlet Valves and Hose Connectivity

Inlet valves are essential connection points that link your vacuum hose to the central system, activating suction as soon as the hose is securely inserted. Once connected, the system creates a sealed air path, enabling efficient cleaning. Here are key aspects to consider: 1. The hose fits securely into the valve, often with locking or bayonet fittings to prevent disconnection. 2. The diameter of the hose and valve typically matches, usually 2 inches. 3. Some valves include electrical contacts to power powered attachments when connected. 4. Automatic lids on certain valves seal tightly when not in use, maintaining ideal suction. Proper connection ensures smooth operation, strong suction, and compatibility with various hose and attachment types. Secure hose connectivity is vital for effective, hassle-free cleaning sound design techniques, ensuring optimal performance of your central vacuum system.

Maintenance for Optimal Performance

Maintaining your built-in vacuum system is key to ensuring consistent performance and longevity. Regularly empty the collection canister or replace disposable bags every 3 to 6 months, using manufacturer-specified types to prevent suction loss and motor strain. Check for cracks, tears, or deformities and replace damaged parts promptly. Don’t overfill to keep airflow efficient. Clean reusable filters every 3 to 6 months and replace disposable filters as recommended to sustain filtration and airflow. Inspect hoses and tubing monthly for cracks or obstructions, clearing debris and avoiding excessive bending. Keep the motor compartment clean, lubricate bearings weekly, and tighten mounts to reduce vibrations. Conduct monthly suction tests and inspect electrical connections to catch issues early, ensuring your system runs smoothly and efficiently. Incorporate simple tools like BTU and CADR calculators to help evaluate and optimize your vacuum system’s performance. Additionally, monitoring system airflow can help identify potential blockages or performance issues before they escalate.

Improving Indoor Air Quality With Built‑In Vacuums

Built-in vacuum systems considerably enhance indoor air quality by capturing dust, allergens, and pollutants before they can circulate throughout your home. By using HEPA filters, these systems trap tiny particles like dust mites and pollen, preventing recirculation and reducing airborne contaminants. Many units vent dirt outdoors, removing pollutants entirely from your living space. This reduces the presence of allergens and irritants that trigger asthma and allergies. The wide piping network allows for thorough cleaning of multiple rooms, ensuring consistent removal of dust and allergens from all areas. Additionally, somatic therapy techniques can help residents manage stress and improve overall well-being, complementing efforts to maintain a healthier indoor environment. As a result, indoor air remains cleaner and healthier. With frequent use, these systems help lower indoor particulate levels, creating a safer environment for sensitive occupants. Overall, built-in vacuums play a crucial role in maintaining superior indoor air quality.

Benefits of Using a Central Vacuum System

Using a central vacuum system offers significant advantages in cleaning power and efficiency. It delivers suction 3 to 5 times stronger than portable vacuums, allowing you to clean carpets, drapes, and furniture more thoroughly in fewer passes. Its larger dirt capacity (5-10 gallons) means you’ll spend less time emptying and more time cleaning. The consistent, powerful suction effectively removes dirt, dust, and debris, saving you effort and time. Plus, you only handle a lightweight hose—often extending 30 feet or more—making multi-room cleaning easy without carrying heavy units. Quiet motors located in remote areas reduce noise inside your home, creating a more relaxing environment. Additionally, Vetted central vacuum systems are known for their durability and long-term reliability, ensuring consistent performance over time. The installation process is straightforward for most homes, offering a seamless integration into your existing cleaning routine. Overall, central vacuums boost cleaning performance, convenience, and home value, making your household maintenance simpler and more effective.

Frequently Asked Questions

How Long Does a Typical Central Vacuum System Last?

A typical central vacuum system lasts 20 years or more with proper maintenance. You’ll find the tubing and in-wall components often last the lifetime of your home, while the motor and canister generally need replacing after 10 to 15 years. Regularly emptying the canister, cleaning filters, and inspecting hoses help extend its lifespan. With good upkeep, your system can remain reliable and efficient for decades.

Can Central Vacuums Be Installed in Existing Homes?

Imagine your home as a canvas waiting for a new brushstroke—you can indeed install a central vacuum system. Skilled professionals will carefully carve pathways through your walls and crawlspaces, connecting inlet valves to a quiet power unit. This seamless integration enhances cleanliness without disrupting your home’s beauty. With thoughtful planning and expert installation, your existing home transforms into a cleaner, more effortless space, ready for a fresh new chapter.

Are Central Vacuum Systems Noisy During Operation?

Central vacuum systems are generally quieter during operation than traditional vacuums. You’ll mostly hear airflow sounds at the cleaning head, which are much softer than motor noises. The main motor is located away from your living space, reducing disturbance. While some noise may come from vibrations or airflow turbulence, installing sound-dampening measures and maintaining the system properly can keep noise levels low, making for a quieter cleaning experience overall.

What Is the Average Maintenance Cost for a Central Vacuum?

You can expect to spend around $150 annually on professional maintenance, which includes inspections, filter changes, and basic system checks. DIY tasks like replacing filters cost less but may risk improper handling, leading to higher expenses. Keep in mind, repair costs vary from $129 to $561 depending on the issue, with labor charges between $15 and $100 per hour. Regular maintenance helps prevent costly repairs and extends your system’s lifespan.

How Energy-Efficient Are Built-In Vacuum Systems?

Built-in vacuum systems are quite energy-efficient. You’ll notice they use less energy overall because they operate mainly during cleaning, with low standby power. The motors are located in ventilated spaces, preventing overheating and reducing energy loss. Plus, their powerful motors clean quickly, saving time and energy, and they contribute to better indoor air quality, which reduces the load on your HVAC system. Overall, they’re a smart, energy-saving choice for your home.

Conclusion

Just as Da Vinci envisioned seamless harmony in design, a central vacuum system brings effortless cleanliness to your home. By understanding its components and maintenance needs, you harness the power of innovation beneath your feet. Embrace this modern marvel, and like a well-orchestrated symphony, your space stays pristine and inviting—showing that true elegance lies in the quiet strength of behind-the-scenes engineering.