If you’re choosing between quartz and nichrome heating elements for your toaster, quartz heats faster, is more energy-efficient, and offers quicker temperature changes thanks to infrared radiation. Nichrome is more durable, resistive to oxidation, and lasts longer, but heats more slowly. Quartz provides precise control, while nichrome handles prolonged use better. To learn more about which material best suits your needs, explore the detailed differences and applications that follow.

Key Takeaways

- Quartz heating elements heat faster and respond more quickly, enabling rapid toasting and precise temperature control.

- Nichrome wires are more durable and resistant to oxidation, offering longer lifespan in toasters.

- Quartz elements provide better energy efficiency due to infrared radiation, reducing power consumption.

- Nichrome is generally less fragile but heats more slowly, leading to longer heating times.

- Both materials’ safety and environmental impact vary, with quartz being fragile and harder to recycle, while nichrome is more robust but more complex to recycle.

Material Composition and Conductivity

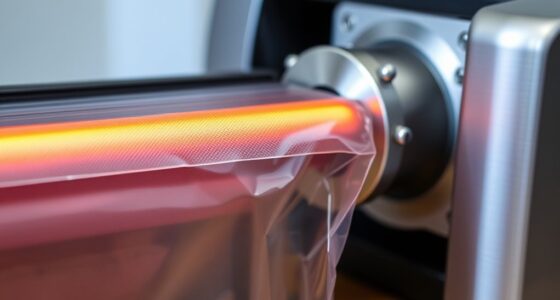

Understanding the material composition of toaster heating elements is essential because it directly influences their electrical conductivity and overall performance. NiChrome, an alloy mainly of nickel (Ni) and chromium (Cr), is the most common material used. Variations include different ratios, like 80/20, 70/30, or 60/16, often with iron (Fe). The 80/20 NiCr alloy, patented in 1906, is especially popular for its stability. Its resistivity allows it to convert electrical energy efficiently into heat. NiCr maintains consistent resistance at high temperatures, typically up to around 1260°C. It develops a protective chromium oxide layer that prevents oxidation, extending its lifespan. NiCr’s high melting point and resistance to oxidation make it suitable for long-term use in high-temperature environments. Quartz, on the other hand, isn’t conductive but houses NiCr wire inside, relying on the alloy’s properties for heating. This composition ensures durability and reliable performance in toaster elements.

Performance and Heating Efficiency

Quartz heating elements respond almost instantly to power, heating up and cooling down rapidly, which allows for precise temperature control and quick adjustments during cooking. This quick response enhances efficiency, as heat is delivered directly through infrared radiation, minimizing energy loss and reducing preheat times. In contrast, Nichrome elements heat more slowly, with a lag between activation and stable heat, leading to potential temperature fluctuations and less efficiency. Quartz’s focused infrared heat results in lower energy consumption—studies show quartz models use about half the energy of traditional ovens for similar tasks. Nichrome’s resistance heating warms air and surfaces gradually, requiring longer operation and more power. Overall, quartz offers superior heating performance, quicker results, and better energy efficiency compared to Nichrome. Additionally, color accuracy and precise temperature control are critical for consistent cooking results, which quartz heating elements can provide more effectively than Nichrome.

Safety Features and User Considerations

You should be aware of safety features like insulation and shielding to prevent burns and electrical shocks from the heating elements. While quartz elements reduce overheating risks through their quick response and radiation control, damaged or broken components can still pose hazards. Regularly inspecting your toaster for physical damage and proper insulation helps guarantee safe operation and longevity. Additionally, understanding the reservoir system of self-watering planters can help prevent overwatering and potential damage to the device. Proper maintenance of the electrical components in your toaster ensures continued safe performance and reduces the risk of malfunctions.

Infrared Radiation Safety

Infrared radiation from toasters is generally safe because it is low-intensity and non-ionizing, meaning it doesn’t have enough energy to damage cells or cause health issues. This type of radiation is common in household items like light bulbs and remote controls, confirming its safety at low exposure levels. Modern toasters include safety features such as automatic shutoffs and thermostats that control heat levels, preventing excessive radiation and overheating. Reflective surfaces inside the chamber direct infrared radiation onto the bread, reducing exposure outside the appliance. To guarantee safe use, place your toaster on heat-resistant surfaces and avoid touching hot components during and immediately after use. Proper maintenance, including cleaning crumb trays, also helps prevent potential hazards related to residual heat and radiant energy. Additionally, understanding the safety features incorporated in modern appliances can further reduce risks associated with infrared radiation. Regular inspections and adherence to manufacturer guidelines ensure optimal appliance safety during operation.

Element Durability and Risks

The durability of toaster heating elements substantially impacts their safety and performance over time. Quartz elements heat quickly but are less robust due to their fragile glass tube, which can break from impacts or grease buildup, risking electrical exposure and fire hazards. They require gentle cleaning and careful handling. Quartz element fragility makes them more susceptible to damage if mishandled or cleaned improperly. Nichrome elements, made of metal alloy wires, are more resilient, resisting oxidation and mechanical wear, but they can develop hot spots, leading to uneven heating and potential safety issues. Over time, oxidation can cause brittleness, raising failure risks. Both types pose risks if damaged: quartz tubes can shatter, and nichrome wires may overheat if insulation fails. Regular inspections and proper maintenance are essential to ensure safety and prolong the lifespan of your toaster’s heating elements. Additionally, understanding the material properties of each element type can help in selecting the most suitable option for longevity and safety.

Durability and Lifespan of Heating Elements

Understanding the durability and lifespan of toaster heating elements depends on several key factors. Material composition plays a big role: quartz elements use quartz glass tubes with tungsten or nichrome filaments, while nichrome elements are made of resistance alloys like Ni90. Operating conditions such as humidity, temperature extremes, and rapid temperature changes can shorten their life. Usage patterns matter too—continuous operation reduces longevity compared to intermittent use. Regular cleaning and proper maintenance are essential for extending lifespan. Quartz elements typically last between 5,000 and 7,000 hours, roughly 500 to 700 days at 10 hours daily. Nichrome’s durability varies based on temperature and exposure to corrosive substances. Overall, quartz heats quickly but isn’t as durable, whereas nichrome withstands high temperatures better, offering potentially longer service lives. Material properties also influence how well each type endures over time, especially considering resistance to corrosion and environmental factors.

Cost Implications and Market Pricing

Nichrome heating elements are generally more affordable than quartz-based counterparts because their manufacturing process is simpler and utilizes well-established techniques. This cost advantage comes from the straightforward production of nichrome wire, which is less complex than fabricating quartz tubes with high-temperature resistance. The typical price for replacement nichrome units ranges from $2 to $7, depending on bulk quantities. In contrast, quartz elements, due to their intricate construction and specialized materials, usually cost $5 to $15 or more per unit. These price differences influence market segmentation: nichrome models dominate budget options, while quartz models target mid- to high-end consumers. The table below highlights the key pricing distinctions:

| Material | Average Cost Range | Key Factors |

|---|---|---|

| Nichrome | $2 – $7 | Simpler manufacturing, commodity metals |

| Quartz | $5 – $15+ | Complex fabrication, high-performance |

Additionally, the choice of material can impact the durability and longevity of the heating element in various applications. Factors such as thermal expansion and resistance to corrosion play crucial roles in the overall lifespan of these elements.

Environmental Impact and Sustainability

You should consider how raw materials like nickel and quartz impact the environment during extraction, with nickel mining being especially resource-intensive. Recycling options for nichrome and quartz vary, affecting waste management and resource conservation. Additionally, energy efficiency during both production and operation influences the overall sustainability of heating elements. Moreover, advancements in automation and robotics, such as those seen in automation technologies, can enhance manufacturing processes, potentially reducing energy consumption and waste.

Raw Material Extraction

Extracting raw materials like quartz and metals for nichrome considerably impacts the environment, often leading to land degradation, habitat loss, and pollution. Quartz mining, typically open-pit, alters landscapes and removes vegetation, disrupting local ecosystems. Dust and airborne particulates from mining degrade air quality and pose health risks. Water runoff carries sediments and chemicals into nearby water bodies, contaminating aquatic environments. Soil erosion and deforestation further threaten sustainability if not managed properly. On the other hand, nichrome’s primary metals—nickel and chromium—require energy-intensive mining and refining, which can cause soil and water contamination through heavy metals and toxic chemicals. Both processes involve significant carbon emissions and ecological disturbance, emphasizing the importance of sustainable practices and responsible sourcing to mitigate their environmental footprints.

Recyclability and Waste

Recycling heating elements from toasters presents significant challenges due to their complex composition. Nichrome alloys, mainly nickel and chromium, are embedded with ceramic and other materials, making separation labor-intensive. Often, recovered nichrome scrap is low-grade, recycled as stainless steel rather than pure alloy, and lacks a dedicated recycling process, reducing incentives. Disposal typically involves standard metal streams, which can introduce contaminants and lower recyclability. Recycling processes for these materials are often limited or inefficient, further hindering sustainable disposal efforts. Quartz heating elements, composed of silica glass tubes with internal wires, are difficult to recycle directly. They require specialized facilities to separate and process the glass, which are less common. Both materials pose environmental risks if improperly disposed of—nichrome can leach heavy metals, while quartz adds to non-biodegradable waste. Limited recycling options increase landfill waste and environmental impact. Additionally, the trustworthiness of recycling processes for these materials is often questionable, further complicating sustainable disposal efforts.

Energy Efficiency Impact

Quartz heating elements are more energy-efficient than nichrome counterparts because they transfer heat primarily through infrared radiation, which directs heat immediately to the food and minimizes loss. This means quartz uses less wattage to reach similar temperatures, reducing overall energy consumption. Additionally, quartz cools quickly when turned off, lowering standby energy use, unlike nichrome, which retains heat longer and draws more power. This efficiency decreases your electricity bills and lessens environmental impact by reducing greenhouse gas emissions from power plants. Furthermore, the material properties of quartz enable faster heat transfer and quicker cooling, enhancing overall energy savings. The ongoing research in AI security vulnerabilities underscores the importance of developing robust safety measures, which can also be applied to improve safety protocols in electrical appliances like toasters.

Applications in Cooking and Food Preparation

Have you ever wondered how different heating elements in your kitchen appliances deliver such precise results? Quartz and Nichrome each excel in specific cooking applications.

- Quartz heaters provide rapid, targeted heat, perfect for toasting bread or browning surfaces quickly. Quick heating capabilities make them ideal for tasks requiring fast response times.

- Nichrome elements produce steady, uniform heat, ideal for baking, simmering, or warming dishes over longer periods.

- Quartz’s infrared radiation ensures efficient surface browning, enhancing crispness and texture.

- Nichrome’s resistive heating supports consistent ambient temperature control for slow cooking or prolonged heating.

- The choice between quartz and Nichrome can also depend on the beach-inspired design and durability considerations, especially in commercial kitchen equipment.

While quartz elements excel in quick, surface-focused tasks, Nichrome’s durability and even heat distribution make it suitable for longer, steadier cooking processes. Each plays a crucial role depending on your food preparation needs.

Future Trends and Technological Innovations

Advancements in materials and technology are driving the future of toaster heating elements, making them more efficient, durable, and versatile. You’ll see innovative materials like graphite and advanced ceramics that distribute heat better and last longer. New designs aim to cut energy loss and boost heat transfer, so your toaster heats faster and more evenly. Smart sensors and algorithms are being integrated to optimize cooking, saving energy and improving results. Sustainability is also a focus, with eco-friendly materials, recyclable parts, and greener manufacturing processes emerging. Technological innovations like graphite heating elements, high-temperature capabilities, and silent infrared operation are transforming toaster performance. These trends help you enjoy faster, smarter, and more eco-conscious toasting experiences while reducing environmental impact. Incorporating sustainable materials and mindfulness techniques into development processes can lead to more thoughtful and sustainable innovations in kitchen appliances.

Frequently Asked Questions

How Do Quartz and Nichrome Elements Compare in Energy Consumption?

You’ll find quartz elements use less energy than nichrome because they heat up faster and transfer heat directly via infrared radiation, reducing waste. Quartz elements typically require lower wattage for the same heating task, making them more energy-efficient overall. Conversely, nichrome consumes steady power but is slower to respond, which can lead to unnecessary energy use during temperature adjustments. So, quartz elements save energy in quick, targeted heating.

Are There Specific Maintenance Requirements for Quartz Versus Nichrome Heating Elements?

Back in the day, folks didn’t have to fuss over delicate tech like quartz heating elements. Today, you need to handle quartz with extreme care—avoid abrasives, moisture, and frequent contact, as it’s fragile and can crack easily. For nichrome, you can clean gently with a damp cloth, and it tolerates light maintenance. Regular inspections help catch issues early, but quartz demands more cautious handling to prevent damage.

Can Quartz or Nichrome Elements Be Repaired or Refurbished?

You generally can’t repair or refurbish quartz or nichrome heating elements effectively. Quartz elements are brittle and prone to cracking, making repairs risky and often impractical, so it’s better to replace them. Nichrome elements can deteriorate over time, but attempting repairs can cause safety issues and damage. Industry standards recommend replacing both types when they fail, ensuring safety and reliable performance rather than risking further damage through repairs.

What Are the Typical Failure Modes for Each Type of Heating Element?

Imagine a delicate glass sculpture versus a sturdy metal coil—each has unique failure modes. For nichrome, you often see wire breakage, corrosion, or poor connections causing failure. Quartz elements tend to crack or break from impact, and internal shorts or fading reduce performance. Both face thermal fatigue and deposit buildup, but nichrome’s weaknesses lie in corrosion and arcing, while quartz struggles with mechanical stress and internal damage.

How Do These Elements Perform in Different Oven Sizes and Designs?

In small ovens, you’ll find quartz elements perform best because they deliver quick, direct infrared heat, making toasting faster. Larger ovens benefit from nichrome coils since they provide more uniform air heating, though slower to respond. Quartz elements might struggle with even heat distribution in bigger spaces unless paired with reflectors. Ultimately, your choice depends on your oven’s size and desired cooking speed and evenness.

Conclusion

In the world of toaster heating elements, choosing between quartz and nichrome boils down to balance and brilliance. By weighing woes and wonders, you’ll wield the wisdom to select a safer, stronger, and sustainable solution. Whether you favor fiery fast heat or durable durability, remember, your decision shapes safety, sustainability, and satisfaction. So, step confidently, select consciously, and savor the sizzling success of your smart, sizzling choice.