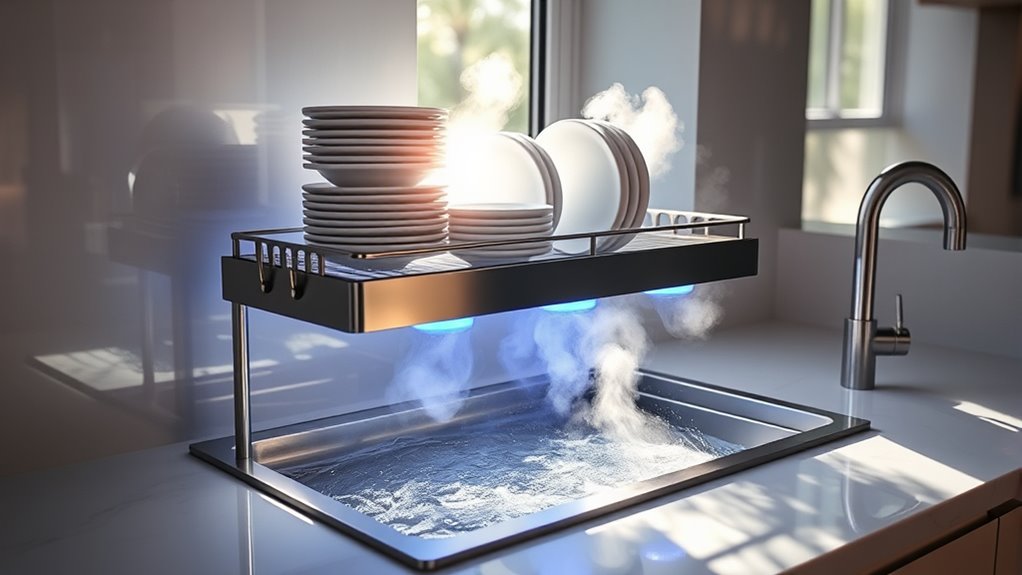

Over-the-sink dish dryers and UV sanitizers use materials like stainless steel, plastics, and silicone to promote hygiene and durability. They rely on gravity and airflow to speed up water drainage and evaporation, while UV-C light disrupts microbial DNA, sterilizing dishes effectively. Incorporating foldable, mesh, or space-saving designs enhances performance and convenience. To understand how these technologies work together to keep your dishes cleaner and dryer, keep exploring the science behind it.

Key Takeaways

- UV-C light damages microbial DNA/RNA, disrupting replication and ensuring effective sterilization of dishes and surfaces.

- Materials like stainless steel and antimicrobial coatings enhance hygiene, durability, and ease of cleaning in over-the-sink dryers and sanitizers.

- Proper water drainage and airflow accelerate drying, reduce residual moisture, and inhibit bacterial and mold growth.

- Adjustable, space-saving designs optimize drying efficiency while fitting limited kitchen spaces.

- Regular maintenance of UV lamps and cleaning components sustain disinfection efficacy and device longevity.

Materials and Design Principles of Over-the-Sink Dryers

Over-the-sink dish dryers are crafted from a variety of materials, each chosen for specific benefits that enhance their functionality and durability. Stainless steel is popular because it resists rust and offers a sleek look, especially grades like 304 stainless steel for corrosion resistance. Carbon steel provides strength and stability but often needs protective coatings to ward off moisture damage. Plastic options are lightweight, affordable, and foldable, making them space-saving, though less durable. Silicone is flexible, soft, and moisture-resistant, ideal for delicate items, and can be rolled up for compact storage. Additionally, silicone’s flexibility allows for innovative design features that improve user experience. Wood offers rustic charm but requires careful maintenance to prevent warping from excess moisture. These materials, combined with smart design principles like adjustability and multi-tier structures, optimize drying efficiency and space use. The choice of electric dirt bike materials and design features can also influence the overall safety and energy efficiency of the product.

Gravity and Airflow: Key Factors in Efficient Water Evaporation

Gravity and airflow work together to make water evaporation on dish dryers more efficient. Gravity helps water flow off dishes by positioning them at an angle, speeding up drainage and reducing residual moisture. Properly inclined dishes allow water to run off quickly, enhancing drying speed. Meanwhile, airflow removes moisture from the surface by continuously exchanging air around the dishes. Good airflow design, such as mesh surfaces or ducts, directs air toward wet dishes, accelerating evaporation. This circulation lowers humidity around the dishes, further speeding drying. When combined, gravity and airflow optimize water removal, minimize drying time, and promote hygiene. Efficient drainage and airflow work hand-in-hand to ensure dishes dry thoroughly, reducing bacterial growth and preventing water spots. Effective design features can significantly improve drying efficiency by enhancing airflow and water runoff, especially when incorporating ventilation systems or adjustable airflow settings. Additionally, incorporating aesthetic wall organization elements can ensure that airflow pathways remain unobstructed, maintaining optimal drying conditions.

The Role of Non-Porous Surfaces in Maintaining Hygiene

Efficient water evaporation on dish dryers depends not only on airflow and drainage but also on the surfaces’ material properties. Non-porous surfaces like glass, certain plastics, and treated metals prevent liquids and microbes from penetrating, reducing microbial reservoirs. These surfaces are easier to clean and disinfect, helping maintain hygiene. They also dry quickly, minimizing moisture retention that promotes microbial growth. To illustrate, consider the following:

| Surface Material | Key Hygiene Benefit |

|---|---|

| Glass | Non-porous, easy to clean |

| PET Plastic | Resistant to staining and chemicals |

| Zinc-Coated Steel | Antimicrobial coatings for ongoing reduction |

| Treated Metals | Durable, chemical resistant |

Using non-porous surfaces in dish drying and sanitizing equipment enhances hygiene by limiting contamination and simplifying maintenance. Additionally, selecting surfaces with microbial resistance properties further supports ongoing cleanliness and safety.

How Foldable and Mesh Structures Enhance Drying Performance

Foldable and mesh structures substantially boost drying performance by enhancing airflow and facilitating water drainage. They allow air to circulate freely around dishes, speeding up evaporation, and ensure water drains efficiently into the sink. Here’s how they improve drying:

- Mesh fabric and grids increase air circulation, promoting faster water evaporation.

- Porous mesh channels water directly into the sink, preventing countertop pooling.

- Foldable racks can expand for larger loads without taking up extra space.

- Sloped surfaces and drain-integrated designs encourage rapid water runoff.

- The use of culturally adapted themes in designs can make these products more appealing in diverse markets.

- Incorporating ergonomic design principles helps users handle and store the racks more comfortably.

These features reduce moisture retention, lower mildew risk, and keep your kitchen cleaner. Lightweight yet sturdy, mesh and foldable frames withstand regular use and cleaning, maintaining peak drying performance over time.

The Science Behind UV-C Light and Microbial Inactivation

UV-C light inactivates microbes by damaging their DNA or RNA, preventing them from replicating or functioning properly. The most effective wavelength is around 260–265 nm, where bacteria and viruses are most vulnerable. This damage leads to mutations and cell death, making UV-C a powerful disinfectant. Mindfulness techniques can enhance focus and safety when using UV-C devices, ensuring proper handling and minimizing exposure risks. Incorporating cybersecurity awareness into safety protocols can help prevent misuse or accidental exposure to UV-C devices.

UV-C Disinfection Mechanism

The disinfection power of UV-C light relies on its ability to damage the genetic material of microorganisms, rendering them inactive. UV-C light, with wavelengths around 254–260 nm, penetrates cells effectively due to its high photon energy. This energy causes multiple effects:

- It forms pyrimidine dimers in DNA and RNA, disrupting replication.

- It induces photoionization, damaging essential biomolecules.

- Cell walls and membranes absorb UV-C, compromising structural integrity.

- Broad-spectrum pathogen inactivation results from combined genetic and cellular damage.

- The effectiveness of UV-C disinfection is enhanced when combined with other hygienic practices, ensuring comprehensive microbial control.

- Proper surface preparation can also improve UV-C disinfection efficacy by reducing shadowing and surface contaminants.

Because of these mechanisms, UV-C can quickly neutralize bacteria, viruses, fungi, and protozoa. The process’s efficacy depends on factors like exposure time, distance, and surface characteristics. This multi-pronged attack explains UV-C’s powerful disinfectant capabilities.

Microbial DNA Disruption

When UV-C light interacts with microbial cells, it causes specific damage to their DNA that leads to inactivation. It primarily forms pyrimidine dimers, such as cyclobutane pyrimidine dimers (CPDs) and 6-4 photoproducts (6-4 PPs), which block DNA replication and transcription. This damage prevents microbes from reproducing, effectively killing or inactivating them. UV-C can also generate oxidative DNA damage indirectly through reactive oxygen species. The extent of damage depends on wavelength, with far-UVC (200–235 nm) being both effective and less harmful to humans. Some microbes have repair mechanisms, like photoreactivation and nucleotide excision repair, which can reverse up to 60% of damage, impacting disinfection efficacy. The severity of DNA disruption ultimately determines microbial viability after UV-C exposure. Additionally, understanding the juice cleansing process highlights how nutrient-rich ingredients can support overall health during detoxification.

Combining Heat, Air Circulation, and UV for Optimal Sterilization

Combining heat, air circulation, and UV light creates an effective sterilization process that guarantees dishes are thoroughly sanitized and dried. This integrated approach targets different bacteria and viruses, ensuring thorough hygiene. Here’s how it works:

- Hot air at 100-200°C kills bacteria and pathogens, sterilizing surfaces.

- Air circulation promotes even drying, preventing moisture buildup that fosters bacteria.

- UV light with wavelengths of 200-300 nanometers effectively destroys remaining microorganisms on all dish surfaces.

- Sealed chambers ensure UV light penetrates deeply, reaching every corner for maximum sterilization.

- Incorporating lifestyle strategies such as maintaining a clean and organized workspace can enhance the efficiency of these sterilization processes.

- Proper maintenance of appliance components ensures consistent performance and safety during operation.

Hygienic Benefits of Elevating Dishes Over Sink Water Levels

Raising dishes above sink water minimizes their contact with residual moisture, considerably lowering the risk of bacterial contamination. By placing dishes on racks above the sink, you limit exposure to bacteria and mold that thrive in damp environments. Air drying promotes evaporation, reducing lingering dampness more effectively than flat countertop drying surfaces. Studies show that air drying decreases bacteria more than towel drying, which can transfer microbes from cloth to dishes. Elevating dishes also separates them from sink water, preventing splash contamination and backflow risks. Proper drainage allows water to drip directly into the sink, avoiding stagnant puddles that foster microbial growth. Additionally, using proper placement ensures optimal airflow and drying efficiency. Proper drainage not only facilitates effective drying but also minimizes water stagnation, which can harbor bacteria. This setup enhances hygiene by confining water and debris to the sink area, making cleaning easier and promoting safer, more sanitary dish handling.

Consumer Trends: Space-Saving Features and Hygiene Technologies

You’re noticing a shift toward space-saving dish racks that fit smaller kitchens and maximize every inch. Hygiene features like drainage systems and UV sanitizers are gaining popularity, offering cleaner, more hygienic drying solutions. As multifunctional designs become more common, consumers prioritize versatility alongside efficient, compact storage options. Incorporating sound design techniques into these products can also enhance user confidence in their hygienic features. Additionally, understanding pregnancy-safe technologies can help manufacturers develop more trustworthy hygiene solutions for health-conscious consumers.

Compact Design Popularity

As urban living spaces shrink, demand for compact dish drying solutions has surged, making over-the-sink dryers and UV sanitizers increasingly popular. You’ll find that these designs maximize limited space and adapt to small kitchens. Consider these key features:

- They optimize vertical space with multi-level or collapsible racks, freeing up counter real estate.

- Many models are modular, allowing you to customize drying capacity without increasing footprint.

- Materials like stainless steel and BPA-free plastics ensure durability while maintaining a slim profile.

- Features such as detachable compartments and non-slip edges boost usability and safety in tight spots.

- Incorporating yoga-inspired design principles can enhance ergonomic comfort and promote a sense of well-being even in small kitchen environments.

These innovations make it easier to dry large volumes of dishes efficiently, all while fitting seamlessly into your compact kitchen.

Hygiene Tech Adoption

The integration of hygiene technologies into compact dish drying units has become a key consumer trend, driven by heightened awareness of kitchen safety and sanitation. You want appliances that not only dry efficiently but actively sanitize your dishes. UV-C light, antimicrobial coatings, and sensor systems are now common, ensuring your dishes are bacteria-free without extra effort. Smart features let you monitor hygiene cycles remotely, adding convenience and peace of mind. Here’s a quick look at key tech adoption factors: effective sanitation methods | Consumer Priorities | Market Drivers |

| ————————————– | —————————————- |

|---|---|

| Active sanitization features | Space-saving, multi-use designs |

| Transparency on efficacy | Urban living demands compact solutions |

| Convenience and automation | Industry standards boost trust |

These innovations meet your need for safe, space-efficient kitchen tools.

Multifunctional Features Rise

Multifunctional features are reshaping the way you approach compact dish drying solutions, especially in urban settings where space is at a premium. You’ll notice that modern racks now include:

- Integrated utensil holders, bowl racks, and knife compartments for better organization.

- Modular, adjustable components that fit various sink sizes and adapt to your needs.

- Multi-tier designs with different-sized compartments to enhance drying and sorting.

- Accessories like hooks, paper towel holders, and fruit baskets that reduce clutter and maximize space. These innovations also support active listening by making kitchen tasks more efficient, reducing frustration and promoting a smoother workflow.

These features help you keep your kitchen tidy, even in small apartments. They also improve functionality without sacrificing capacity, making your limited counter space more efficient and your kitchen more organized. Incorporating space-saving features is a key trend in modern kitchen appliances to optimize small-area environments.

Material Selection and Maintenance for Long-Term Sanitation

Choosing the right materials for over-the-sink dish dryers and UV sanitizers is essential to guarantee long-term sanitation and device durability. Use corrosion-resistant materials like stainless steel and food-grade plastics to withstand humid, wet environments. Quartz sleeves are ideal for UV lamps because they transmit UV light effectively and resist degradation. Avoid materials that absorb UV or degrade under UV exposure, which can reduce sanitizer effectiveness. Components in contact with water should be antimicrobial or easy to sanitize, preventing microbial buildup. Regular maintenance includes unplugging the device before cleaning, removing and washing drip trays, protective screens, and brush holders with warm soapy water. Clean the UV lamp and quartz sleeve with mild acids like vinegar, avoiding abrasives. Replace UV lamps every 12,000 hours or when UV output drops. Incorporating HEPA filtration in the design can further improve air and water quality by capturing fine particles and allergens, enhancing long-term sanitation performance.

Frequently Asked Questions

How Does UV-C Light Sanitize Dishes Without Damaging Them?

You might wonder how UV-C light sanitizes dishes without causing damage. It works because UV-C has a shallow penetration depth, targeting only surface microbes without affecting the dish material. The doses used are carefully calibrated to kill bacteria and viruses effectively while avoiding material degradation. Plus, UV-resistant materials and controlled exposure times prevent fading, brittleness, or discoloration, ensuring your dishes stay safe and undamaged during the sanitization process.

Are Foldable Dish Dryers as Durable as Fixed Models?

Imagine a sturdy bridge standing strong after years of traffic—that’s how fixed dish racks compare to foldable ones. Fixed models, made from heavy-gauge stainless steel or welded joints, offer greater durability, supporting heavy pots without wobbling. Foldable racks, though convenient, have hinges and softer materials like silicone that may wear with repeated use. So, if longevity matters, fixed racks are your more reliable, long-lasting choice.

Can UV Sanitizers Kill Viruses on All Types of Dish Materials?

UV sanitizers can effectively kill viruses on many dish materials, especially smooth, non-porous surfaces like glass, stainless steel, and plastics. However, porous or textured materials like sponges, some plastics, or organic residues may shield microbes, reducing UV effectiveness. To maximize disinfection, you should clean dishes beforehand and guarantee proper exposure time. Keep in mind, UV light works best when there are no shadows or obstructions blocking the rays.

How Often Should I Clean and Disinfect My Over-The-Sink Rack?

You should clean and disinfect your over-the-sink rack at least once a week, more often if it’s used frequently. Dismantle it, scrub with mild soap, rinse with hot water, and sanitize with UV or dishwasher if possible. Dry thoroughly to prevent rust and mold growth. Regular maintenance reduces bacteria, prolongs the rack’s lifespan, and keeps your kitchen hygienic and visually appealing.

Do Different Materials Affect the Drying and Sanitizing Efficiency?

Yes, different materials impact drying and sanitizing efficiency. Silicone and stainless steel allow UV light to penetrate effectively, ensuring thorough sanitization and quick drying. In contrast, wood and thick plastics can block UV exposure, reducing sanitization effectiveness. Smooth surfaces like silicone and stainless steel resist microbial buildup, making cleaning easier and maintaining hygiene. Choose durable, UV-transparent materials to optimize both drying speed and sanitizing performance in your kitchen.

Conclusion

By understanding the science behind over-the-sink dish dryers and UV sanitizers, you can make smarter choices for your kitchen. These innovations combine materials, airflow, and UV technology to keep your dishes spotless and hygienic. Remember, a clean kitchen is a happy one—an ounce of prevention is worth a pound of cure. Embrace these space-saving, hygienic solutions, and you’ll find that a well-designed drying system truly makes all the difference.