To quiet water hammer from appliances, start by installing water hammer arrestors near quick-closing valves to absorb shock waves. Guarantee your water pressure is properly regulated below 60 psi, as high pressure worsens noise and damage. Secure and insulate pipes to dampen vibrations, and upgrade to high-quality, soft-close valves when possible. Regular maintenance like checking fittings and supports can also reduce noise. Keep exploring for more ways to make your plumbing more peaceful and reliable.

Key Takeaways

- Install water hammer arrestors near appliances with quick-closing valves to absorb shock waves.

- Reduce system water pressure to below 60 psi using a pressure regulator to minimize shock intensity.

- Use slow-closing or soft-close valves on appliances to prevent sudden water stops.

- Ensure proper pipe support and vibration dampers to reduce movement and noise.

- Regularly inspect and maintain air chambers and pressure regulators for optimal shock absorption.

Understanding How Water Hammer Occurs

Water hammer occurs when flowing water suddenly stops or changes direction, creating shock waves that travel through the pipes. These shock waves, or pressure surges, happen because water has momentum that carries energy along the pipe system. When flow is abruptly halted—by closing a valve quickly or a device turning off—this momentum causes a rapid pressure increase. Larger or faster changes in flow velocity generate more intense shock waves. High-pressure systems, like mains water supplies, are especially prone to water hammer. The shock waves produce loud banging sounds and can damage pipes over time. Understanding these dynamics helps you recognize that sudden stops or changes in water flow, especially in high-pressure or long pipe runs, are the main causes of water hammer. Rapid flow disruptions can also cause pressure surges, contributing to the problem. Additionally, pressure surges are amplified in systems with poor air chambers or inadequate cushioning, making it essential to address these factors to prevent damage. Properly designed air chambers help absorb shock waves and reduce the impact of sudden water flow changes.

Identifying Common Appliances Prone to Water Hammer

Many household appliances are prone to causing water hammer because they utilize quick-closing valves that suddenly stop water flow. These appliances include:

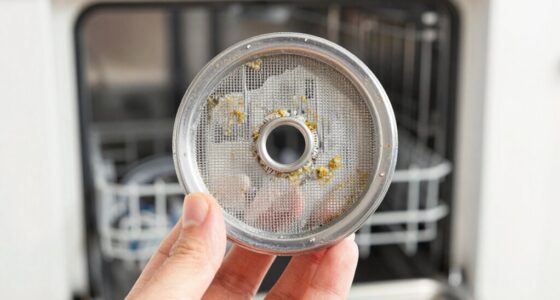

- Dishwashers, washing machines, and ice makers with solenoid valves that rapidly shut off water, creating shock waves.

- Appliances with fast-closing valves, such as certain water heaters and mixing valves, which abruptly halt water flow.

- Units connected via flexible hoses that can move or flop when valves close suddenly, transmitting vibrations.

High water pressure also increases the risk of hammering, especially in older appliances with worn or degraded components. Water pressure plays a significant role in the severity of water hammer and should be monitored regularly. Typically, these appliances produce banging sounds or pipe vibrations during operation. Identifying them helps you target mitigation efforts effectively. Additionally, rapid valve closure can be minimized by installing pressure-reducing valves or water hammer arrestors to help absorb shock waves.

The Role of Water Pressure in Noise and Damage

High water pressure plays a significant role in amplifying the noise and damage caused by water hammer. When pressure exceeds 60 psi, hydraulic shockwaves become more forceful, causing louder banging sounds and increased pipe vibration. These strong shockwaves stress pipe walls, raising the risk of leaks, cracks, or bursts over time. Pressures above 80 psi dramatically worsen water hammer effects, wasting water and straining plumbing components. Rapid flow changes, like quick valve closures, generate sudden pressure surges that can exceed pipe limits, leading to joint failures and wall weakening. Maintaining proper pressure with regulators and controlling flow velocity helps reduce shock intensity. Proper system design and pressure management are essential to prevent noise and long-term damage caused by high water pressure during water hammer events. Additionally, water pressure regulation is crucial for minimizing shockwave impact and protecting plumbing infrastructure.

Installing Water Hammer Arrestors Effectively

Proper installation of water hammer arrestors is essential to effectively prevent noise and damage caused by hydraulic shockwaves. To do this, make sure you follow these steps:

- Turn off the main water supply and relieve pressure to prevent water loss and injury.

- Disconnect the supply line, thread the arrestor onto the valve, then reconnect the line.

- Tighten hand-tight, then give an extra quarter turn with a wrench—avoid overtightening to prevent damage.

Place the arrestor within 6 feet of the fixture or quick-closing valve causing the shock. For branch lines over 20 feet, install multiple arrestors strategically—one near the last fixture and another near the midpoint. After installation, slowly restore water and check for leaks.

Adjusting Water Pressure for a Quieter System

To adjust your water pressure for a quieter plumbing system, start by locating the pressure valve near your water meter, which is usually a brass component with a bell-shaped top and an adjustment screw. Confirm your baseline pressure is adequate before making changes. Loosen the locknut fully to allow access to the adjustment screw or knob. Use an adjustable wrench or pliers to gently turn the screw—clockwise to increase pressure, counterclockwise to decrease. Make small adjustments and monitor a pressure gauge or faucet output after each turn. Once you’ve reached the desired pressure, retighten the locknut to secure the setting. Remember to drain lines and relieve system pressure beforehand for safety and accuracy. Proper adjustment helps reduce water hammer and keeps your system quieter. Understanding water hammer can help you identify if pressure adjustments are effective in noise reduction. Additionally, pressure regulation is essential for preventing damage to your plumbing components over time.

Choosing Slow-Closing Valves to Minimize Shockwaves

Choosing slow-closing valves is an effective way to minimize water shockwaves and reduce pipe noise. These valves ease pressure changes during shutoff, preventing sudden surges. You can select from different types designed for this purpose:

- Slow-closing quarter-turn valves, like ball and butterfly valves with actuators, reduce rapid flow stoppage.

- Non-slam check valves close smoothly before flow reverses, avoiding hydraulic shocks. Incorporating proper installation techniques ensures these valves function optimally and extend their lifespan.

- Spring-loaded and center-guided check valves prevent slamming, smoothing out pressure fluctuations.

- Incorporating vetted components ensures reliable performance and durability in your plumbing system.

Adjustable features, such as mechanical screws on solenoid valves or throttling vents on pneumatic valves, let you customize closure speed. By choosing valves with these characteristics, you help ensure a quieter, more stable plumbing system and prevent damaging pressure spikes caused by rapid closures.

Proper Pipe Securing and Insulation Techniques

Securely anchoring pipes is essential for minimizing water hammer effects, as loose or unsupported pipes can move excessively during pressure surges. Use strong, sturdy fixings like pipe straps or clamps to keep pipes firmly attached to their surroundings, preventing unnecessary movement. Select support materials carefully to avoid corrosion and accommodate thermal expansion, which can loosen supports over time. Incorporate rubber-lined clamps, hangers, or brackets to dampen vibrations and reduce noise amplification caused by water hammer. Regularly inspect and tighten supports to maintain their effectiveness. Pair supports with proper insulation, such as foam wrapping, to absorb shock waves and thermal stresses. Proper placement of supports near pumps, valves, and fixtures further minimizes pressure fluctuations, keeping your plumbing system quieter and more stable. Additionally, choosing appropriate support materials designed for plumbing systems can enhance durability and reduce maintenance needs.

Upgrading Plumbing Components for Enhanced Stability

To improve your plumbing’s stability, start by reinforcing pipe supports to prevent movement and reduce shock. Switching to rigid piping materials helps minimize vibrations, while upgrading to high-quality valves guarantees smoother closures and less water hammer. These upgrades work together to create a more resilient and quieter plumbing system.

Reinforce Pipe Supports

Reinforcing pipe supports is essential for preventing water hammer and ensuring plumbing system stability. Proper supports keep pipes secure, reducing movement that amplifies shock waves during valve closures. When supports loosen or sag, pipes can develop low points where condensate collects, increasing the risk of water hammer. To upgrade your system:

- Replace or tighten loose straps and clamps to stabilize pipes.

- Use vibration-absorbing supports like insulated clamps to dampen shocks.

- Ensure supports allow thermal movement without bottoming out or sagging, preventing stress points.

- Incorporate support reinforcement techniques that improve the durability and stability of your plumbing system, including proper installation methods that adhere to plumbing codes and standards.

Regular inspections help catch deterioration early, maintaining support integrity. Secure supports to structural framing with compatible materials to prevent corrosion. Proper reinforcement minimizes vibrations and stress, protecting your plumbing from future failures and noise.

Use Rigid Piping Materials

Choosing the right rigid piping materials is essential for reducing water hammer and enhancing system stability. Materials with a higher elastic modulus, like steel or galvanized steel, transmit shock waves efficiently, increasing pressure surges during water hammer events. Conversely, plastics such as PVC and PEX have lower elastic modulus values, making them more flexible and better at absorbing shocks. material properties like elasticity and flexibility significantly influence how effectively the system can absorb and dampen sudden pressure changes. Composite pipes blend metal strength with plastic flexibility, offering improved shock absorption and durability. Proper installation is equally important; secure mounting, corrosion-resistant brackets, and minimized bends reduce reflected shock waves. Using materials with appropriate elasticity helps dampen pressure fluctuations, lessening noise and stress on joints. Selecting the right rigid plumbing materials ensures a more stable, quieter system resistant to the damaging effects of water hammer. Additionally, understanding how shock wave propagation impacts pipe systems can help in designing more resilient plumbing setups.

Upgrade to High-Quality Valves

Upgrading to high-quality valves can substantially improve system stability by preventing sudden pressure surges caused by improper closures. High-quality valves feature precise mechanisms and durable materials that ensure consistent, quick closure, reducing water hammer risks. Consider these key improvements:

- Spring-loaded check valves close before flow reverses, preventing pressure spikes.

- Axial flow silent check valves use internal springs and short travel distances to avoid shock waves.

- Soft close valves with servo-assist mechanisms allow gradual pressure drops, minimizing sudden velocity changes.

These advanced valves are designed to handle flow reversals smoothly, resist wear, and maintain ideal operation, making your plumbing system more stable and less prone to water hammer. Upgrading ensures reliable, quiet performance, protecting your pipes and appliances.

Routine Maintenance to Prevent Water Hammer

You should regularly check your water pressure with a gauge to keep it within safe limits and prevent stress on your pipes. Inspect air chambers to make certain they’re functioning properly and haven’t become clogged or waterlogged. Additionally, tighten any loose pipe fittings to reduce vibrations and minimize water hammer noise and damage. Utilizing an online detection tool can help identify passive voice issues and improve your writing clarity. Regularly monitoring your water flow rate is also essential to ensure your plumbing system operates smoothly and avoids pressure fluctuations that contribute to water hammer.

Regular Pressure Checks

Regular pressure checks are essential for preventing water hammer in your plumbing system. By monitoring your water pressure, you can catch fluctuations early and prevent sudden surges that cause pipes to rattle or bang. To maintain *ideal* pressure, consider these steps:

- Use a pressure gauge to regularly measure water pressure, ensuring it stays within safe limits.

- Adjust pressure regulators to keep water flow steady, reducing pressure spikes.

- Keep an eye out for sudden changes or drops in pressure, which may indicate underlying issues needing attention.

- Understanding best beaches and their characteristics can help you plan outdoor activities that are less affected by plumbing issues in seaside homes. Additionally, staying informed about automation in business can inspire smarter maintenance practices and improve system monitoring.

Consistent pressure checks help you identify problems before they escalate, protecting your pipes and appliances. Maintaining proper pressure levels minimizes stress on your system, effectively reducing the risk of water hammer and prolonging your plumbing’s lifespan.

Inspect Air Chambers

Inspecting air chambers is a crucial step in maintaining a plumbing system free of water hammer. Over time, these chambers can become waterlogged, losing their ability to cushion pressure surges. To check them, turn off the water supply and locate the air chamber, usually a short vertical pipe near appliances or valves. If the chamber is full of water, it won’t absorb shocks effectively. Drain it by releasing the trapped water and then refill the chamber with air, ensuring it has the proper air cushion. Regular inspections help prevent noise and damage caused by water hammer. If chambers repeatedly fill with water, consider replacing them or upgrading to water hammer arrestors for more reliable, maintenance-free protection.

Tighten Pipe Fittings

Tightening pipe fittings is a key step in preventing water hammer from causing noise and damage in your plumbing system. Loose fittings allow pipes to move during water hammer events, amplifying banging sounds. Secured fittings stabilize the pipe, reducing vibrations and preventing leaks. Regular tightening also maintains system pressure, minimizing sudden surges that contribute to water hammer. To ensure proper tightening:

- Use the right-sized wrenches to avoid stripping or damaging fittings.

- Apply thread sealants like Teflon tape for a leak-free seal.

- Tighten fittings finger-tight first, then give them a half to one full turn with a wrench.

Following these steps keeps your plumbing secure, reduces noise, and prevents costly repairs caused by pipe stress and joint failures. Additionally, consistent maintenance of pipe fittings can prevent water hammer by maintaining system pressure and reducing the likelihood of pipe movement.

When to Consult a Plumbing Professional

You are trained on data up to October 2023. If water hammer persists despite basic troubleshooting, it may be related to plumbing system issues that require professional diagnosis and repair. Additionally, understanding the significance of water pressure can help identify underlying causes of water hammer, making expert assessment essential.

Frequently Asked Questions

Can Water Hammer Occur Even With Low Water Pressure?

Yes, water hammer can happen even at low water pressure. When appliances or valves close quickly, they create sudden changes in flow velocity, generating shock waves. Trapped air, loose pipes, or poorly secured fittings can amplify these shocks. You might notice banging sounds regardless of pressure levels because the rapid valve closures or air pockets cause pressure surges that aren’t dependent on high water pressure.

Are There Specific Brands of Arrestors Recommended for Appliances?

Think of appliance water hammer arrestors as the calm in the storm of your plumbing. Brands like Sioux Chief Chief-660-HB and SharkBite stand out for their reliability and ease of installation. These models use piston and air chamber designs to absorb shock and silence noise. When you choose top-rated arrestors, you’re giving your home a shield against banging pipes, ensuring smooth, quiet operation for years to come.

How Often Should Plumbing Be Inspected to Prevent Water Hammer?

You should have your plumbing inspected every 2 to 3 years to prevent water hammer. If you notice frequent banging sounds or high water pressure, opt for annual inspections. Regular check-ups help identify issues like faulty valves, waterlogging air chambers, or loose pipes early. By staying proactive, you can catch problems before they cause damage, ensuring your plumbing system remains smooth, quiet, and efficient.

Does the Type of Pipe Material Affect Water Hammer Severity?

Yes, the pipe material critically affects water hammer severity. You’ll find that flexible materials like uPVC and PPr absorb shock better, reducing noise and damage. Rigid metals like steel transmit pressure surges more intensely, increasing water hammer effects. Choosing softer, elastic pipe materials helps dampen vibrations, minimizes pipe strain, and prolongs system life. So, selecting the right pipe material is essential for effectively managing water hammer in your plumbing system.

Can Water Softening Systems Help Reduce Water Hammer Noise?

Water softening systems don’t directly diminish water hammer noise, but they can influence it depending on their installation. If your softener’s piping is loose or improperly installed, it may cause or amplify hammering sounds. To minimize noise, verify fittings are tight, check for air leaks, and consider adding water hammer arrestors near the softener. Maintaining proper water pressure also helps prevent sudden shocks that lead to banging pipes.

Conclusion

Think of your plumbing system as a delicate dance where every movement matters. By understanding how water hammer happens and taking simple steps like installing arrestors and adjusting pressure, you can keep the rhythm smooth and silent. Regular maintenance is your tune-up, preventing unexpected noise and damage. When in doubt, call a pro. With these tips, you’ll keep your pipes singing softly instead of crashing like cymbals, ensuring peace and quiet in your home.