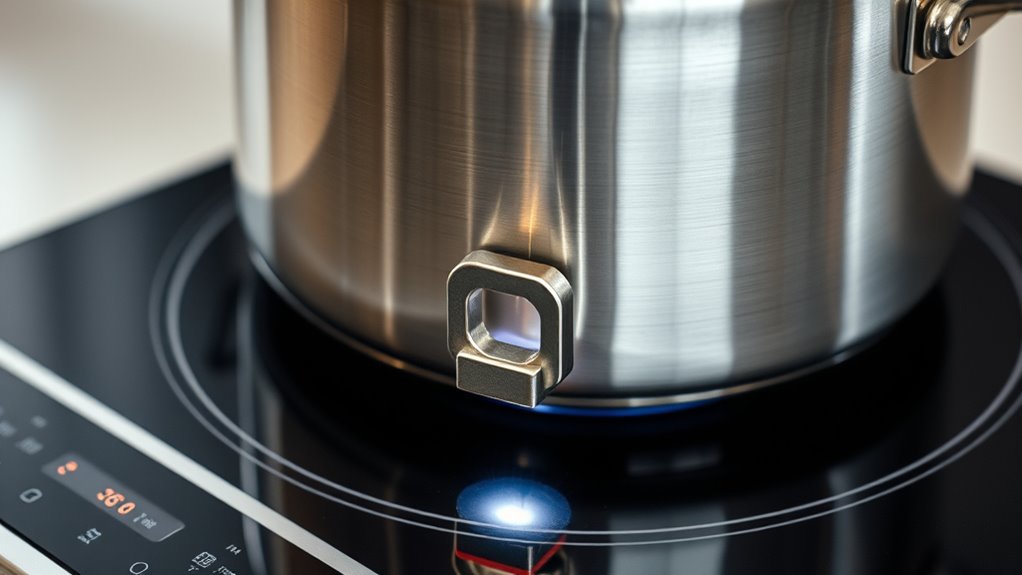

Using a magnet to test your cookware works because it reveals if the material is ferromagnetic, which is essential for induction cooking. When a strong magnet sticks firmly, it means the cookware contains magnetic metals like cast iron or certain stainless steels that respond well to induction fields. If the magnet doesn’t stick, it likely isn’t suitable for induction. To find out more about how this simple test confirms compatibility, keep exploring the details below.

Key Takeaways

- The magnet test detects ferromagnetic materials needed for effective induction heating.

- Magnetic permeability influences how well cookware responds to the induction cooktop’s magnetic field.

- A strong magnet attachment confirms the presence of ferromagnetic layers suitable for induction.

- The test is simple, quick, and relies solely on magnetic response to assess compatibility.

- External factors like surface cleanliness and magnet strength can affect test accuracy.

The Science Behind Magnetic Properties in Cookware

Understanding the science behind magnetic properties in cookware is essential for grasping how induction cooking works. Magnetic permeability (μ) measures how easily a material supports a magnetic field, directly affecting induction efficiency. Ferromagnetic materials like cast iron and certain stainless steels have high permeability, enabling strong magnetic coupling with the induction coil. This causes induced currents to concentrate near the surface, increasing heat generation. Materials with low permeability, such as copper or aluminum, don’t respond well to magnetic fields and can’t generate sufficient eddy currents, making them unsuitable for induction. The permeability’s effect varies with frequency, as typical induction cookers operate between 25 and 50 kHz. High permeability materials ensure effective energy transfer, resulting in faster, more efficient heating of the cookware. Electrons in ferromagnetic materials have unbalanced spins, creating tiny magnets, which further enhances their magnetic response. Additionally, the magnetic response of a material can be influenced by its composition and treatment, impacting induction performance.

How the Magnet Test Detects Induction Compatibility

The magnet test works by checking if your cookware has enough ferromagnetic material to respond to an induction cooktop’s magnetic field. When you place a strong magnet on the bottom of your pot or pan, a firm attachment indicates the presence of ferromagnetic material capable of induction heating. If the magnet sticks steadily without slipping, your cookware can generate heat efficiently on an induction stove. Conversely, weak or no attraction suggests the material isn’t suitable for induction, meaning it won’t heat properly or may not work at all. This quick test helps you identify compatible cookware without specialized tools. This method is effective because the magnet only detects magnetic response, not the quality or thickness of the material, so some cookware might pass or fail based solely on ferromagnetic content. Additionally, understanding induction compatibility can help prevent frustration and ensure your cookware performs as expected. To improve your testing accuracy, ensure the magnet is strong enough and consistently applied to the cookware’s base.

Materials That Are Naturally Magnetic and Suitable for Induction

Materials that are naturally magnetic and suitable for induction heating include cast iron, carbon steel, stainless steel (ferromagnetic grades), enameled cast iron, and magnetic stainless steel plates or bases. Cast iron is primarily iron, making it highly ferromagnetic and excellent for induction cooking, with great heat retention and durability. Carbon steel, also iron-based, heats quickly and responds well to temperature changes, ideal for professional chefs. Certain stainless steel grades, like 18/0, contain magnetic elements and work with induction, especially when combined with an aluminum or copper core. Enameled cast iron shares the magnetic properties of cast iron but adds a corrosion-resistant finish. Magnetic stainless steel plates or bases are used to convert non-magnetic pans into induction-compatible cookware. Additionally, choosing cookware with appropriate magnetic properties ensures optimal performance on induction cooktops. Recognizing ferromagnetic materials is essential for selecting effective cookware, as only they can generate heat efficiently on induction surfaces.

Construction Features That Enhance Magnetic Response

Your cookware’s magnetic layer placement and multi-layered base design directly affect induction performance. Properly positioned ferromagnetic layers and carefully engineered multi-layer structures maximize magnetic response and heat transfer. Understanding these construction features helps you choose cookware that heats efficiently and evenly on induction cooktops. Additionally, incorporating personalized care practices can optimize your cooking experience and extend the lifespan of your cookware. The use of high-quality materials and precise manufacturing techniques further enhances the cookware’s magnetic responsiveness, leading to more consistent heating results.

Magnetic Layer Placement

Positioning the magnetic layer as the outermost base is essential for maximizing induction efficiency. When you place the magnetic layer directly beneath the cooking surface, it ensures maximum magnetic flux penetration, leading to better heating responsiveness. Ferromagnetic stainless steel or cast iron used as the outer layer effectively triggers eddy currents in the cookware base, producing rapid, uniform heat. Proper placement also improves magnetic contact with the cooktop, especially if the surface is flat and milled, enhancing magnetic coupling. While other layers like aluminum or copper provide heat conduction, they don’t interfere with magnetic activation if positioned correctly. This strategic placement ensures your cookware responds swiftly to the induction field, delivering even heat distribution and optimal cooking performance. Additionally, ensuring the magnetic layer is free of damage or corrosion helps maintain efficient magnetic response over time. Maintaining the magnetic properties of the layer is crucial for consistent performance.

Multi-layered Base Design

Multi-layered base design enhances magnetic response by carefully combining different metals to optimize both heat conduction and electromagnetic performance. You’ll find ferromagnetic stainless steel on the outer layer, ensuring compatibility with induction cooktops, while inner layers like aluminum or copper provide excellent thermal conductivity for even heat distribution. The stainless steel used, often 18-8 or 18-10 grade, balances durability and magnetic permeability. Layer thickness is calibrated so the ferromagnetic steel is thick enough for strong magnetic induction without adding excessive weight. Thin, flat middle layers prevent hotspots and promote uniform heat transfer. The multiple layers, often arranged in a 7-ply or triple-clad structure, are precisely milled for flatness, enhancing induction coil coupling and magnetic response. This design guarantees efficient, stable heating across the cookware surface.

Practical Steps for Conducting the Magnet Test

Before conducting the magnet test, gather a strong magnet such as a refrigerator or neodymium magnet, and verify the cookware is clean and dry. Proper preparation helps avoid false results caused by grease or moisture. Place the cookware on a stable, flat surface, and identify the flat bottom, which contacts the cooktop. Use good lighting to observe the magnet’s behavior. Hold the magnet firmly against the center of the bottom. Check for strong, direct adhesion without slipping. Test multiple points, especially if the cookware has layered materials. Repeat if needed for consistency. If the magnet quickly disengages, the cookware isn’t suitable for induction. Proper testing guarantees accurate results and helps you avoid buying incompatible pots. Understanding the induction compatibility of cookware is essential for efficient cooking and appliance longevity.

Limitations and Considerations When Using a Magnet Test

While a magnet test can be a quick way to check if cookware might work with induction, it has notable limitations that you should consider. Magnetic force varies depending on the cookware’s base composition, so a weak magnet may falsely suggest incompatibility, even if the cookware heats properly. Some pots have ferromagnetic layers only in parts of the base, causing inconsistent responses. Composite or multilayered cookware might pass the magnet test but perform poorly or unevenly on induction. Additionally, magnet tests can’t measure magnetic permeability or electrical resistance, both critical for efficient heating. External factors like cleanliness, surface shape, or magnet strength can also impact results. Remember, passing the magnet test doesn’t guarantee optimal induction performance, so supplement with actual cooking trials. According to Glycolic Acid Benefits for Skin, testing with a magnet is a simple initial step but should not be solely relied upon for determining induction compatibility. For a more accurate assessment, understanding induction cookware materials and their properties is essential.

The Role of Material Resistance and Magnetic Permeability in Induction Heating

Material resistance and magnetic permeability are fundamental to how effectively cookware heats in induction cooking. High magnetic permeability, found in ferromagnetic materials like ferritic stainless steel and iron, enhances the interaction with the magnetic field, increasing induced currents. These unbalanced electron spins create atoms that act like tiny magnets, aligning under magnetic influence and enabling efficient heating. A higher permeability reduces skin depth, concentrating currents near the surface and boosting heat generation. Conversely, non-magnetic metals like austenitic stainless steel or aluminum have low permeability, resulting in weak induction performance. The magnetic properties directly influence the strength of eddy currents, which are essential for Joule heating. Knowing how material resistance and permeability work together helps you understand why some cookware heats better in induction stoves. Additionally, advances in AI-driven security systems are shaping the future of smart kitchen appliances, making them safer and more efficient. For example, magnetic properties dictate the effectiveness of cookware in induction environments, emphasizing the importance of selecting the right materials.

Benefits of Verifying Cookware With a Magnet Before Cooking

Using a magnet to test your cookware guarantees it’s compatible with induction stoves, so you won’t waste time or money on the wrong pans. It quickly confirms whether the material will heat properly, preventing cooking failures. This simple step helps you cook safely and efficiently without surprises. Additionally, understanding the best cookware materials can improve your overall cooking experience.

Ensures Induction Compatibility

Verifying that your cookware is induction-compatible before cooking guarantees your stove works efficiently and prevents wasted energy. A magnet test quickly shows if your pots and pans contain enough ferromagnetic material to generate heat through electromagnetic fields. If the magnet sticks strongly, your cookware will be detected and heated properly, ensuring peak performance. Conversely, weak magnetism indicates poor induction compatibility, which could lead to ineffective heating. This simple check helps you avoid using incompatible cookware that won’t work on your induction stove, saving time, money, and energy. It also provides confidence in your cookware choice, confirming it meets the operational requirements for safe and efficient cooking. Overall, magnet testing ensures your induction cooktop functions as intended with compatible cookware every time.

Prevents Cooking Failures

By confirming your cookware’s magnetic properties with a simple magnet test before you start cooking, you can prevent unexpected failures during meal prep. Cookware without magnetic features won’t heat on induction stoves, leading to wasted time and effort. If the magnet only partially attracts, it indicates mixed metals, which can cause uneven or insufficient heating, risking undercooked or burnt food. Non-magnetic materials like aluminum, glass, or ceramic won’t work unless paired with a converter disc, so testing prevents using incompatible cookware. This quick check saves you from frustration and energy waste, ensuring your cookware will heat properly and consistently. Avoiding these failures means smoother cooking, fewer surprises, and better meal quality every time.

Frequently Asked Questions

Can a Magnet Test Confirm Cookware’s Overall Durability or Only Induction Compatibility?

A magnet test only confirms if your cookware is compatible with induction, not its overall durability. You might pass the magnet test but still have cookware prone to warping, chipping, or surface damage. To gauge durability, look for quality materials, construction, and brand reputation. Remember, the magnet test is a quick, simple check, but it doesn’t tell you how well your cookware will hold up over time or under frequent use.

Do All Magnetic Materials Perform Equally Well in Induction Heating?

You can’t assume all magnetic materials perform equally in induction heating. Some, like ferritic steels, heat quickly thanks to magnetic hysteresis, while others, like certain stainless steels, don’t heat as well if they’re less magnetic. Even within magnetic materials, factors like alloy composition and thickness influence efficiency. So, it’s a case of apples and oranges—you need to check the specific material properties to predict performance accurately.

How Does the Thickness of Cookware Affect the Magnet Test Results?

The thickness of your cookware’s magnetic base impacts magnet test results because a thicker, ferromagnetic layer produces a stronger magnetic pull, indicating better induction compatibility. If the base is too thin, the magnet may still stick, but the cookware might heat unevenly or slowly on an induction cooktop. Thicker bases generally mean more efficient heating, so check the base’s thickness to guarantee better performance beyond just passing the magnet test.

Is a Weak Magnet Attachment an Indication of Poor Induction Performance?

A weak magnet attachment suggests the cookware might not perform well on an induction cooktop. It indicates less magnetic material or poor bonding, which can cause uneven heating or slower response times. However, it isn’t a definitive test—some cookware may still work despite weak magnetism. To be sure, check for an induction symbol and test the cookware with actual cooking to confirm its performance.

Can Non-Magnetic Cookware Be Modified to Work With Induction Stoves?

Yes, you can modify non-magnetic cookware for induction stoves by attaching a ferromagnetic disk or plate to the bottom. This magnetic base acts as a conductor for the induction field, enabling heat generation. Make sure the magnetic plate matches the size and flatness of your burner for efficient heating. Keep in mind, some cookware may still heat unevenly, so choosing quality adapters and ensuring proper fit are essential.

Conclusion

By mastering the magnet method, you make meal prep more manageable and your cookware more compatible. Recognize the magnetic magic that makes induction cooking efficient and effortless. With a simple swipe of a magnet, you guarantee your pots and pans perform perfectly under the powerful pull of induction. So, stay savvy, test thoroughly, and trust the technique to transform your cooking experience—making your kitchen smarter, safer, and more satisfying.