In your dishwasher, the pump type affects how water circulates and cleans dishes. Common pumps include centrifugal, axial, and reversible models, each with unique spray patterns for thorough coverage. Spray arms are strategically placed and designed to maximize water distribution, reducing blind spots. Advanced designs improve efficiency, quiet operation, and cleaning power. To learn how these components work together for ideal performance, keep exploring the details behind dishwasher hydraulics.

Key Takeaways

- Reversible pumps switch motor direction to alternate between washing and draining, improving water circulation flexibility.

- Centrifugal pumps use high-speed impellers to generate pressure, ensuring even spray coverage from bottom to top.

- Variable-speed ECM motors allow precise water flow control, optimizing spray patterns and energy efficiency.

- Spray arm placement (bottom, middle, top) and nozzle orientation significantly impact coverage and cleaning effectiveness.

- Hydraulic components like diverters and control valves regulate water flow, supporting consistent spray patterns and pressure.

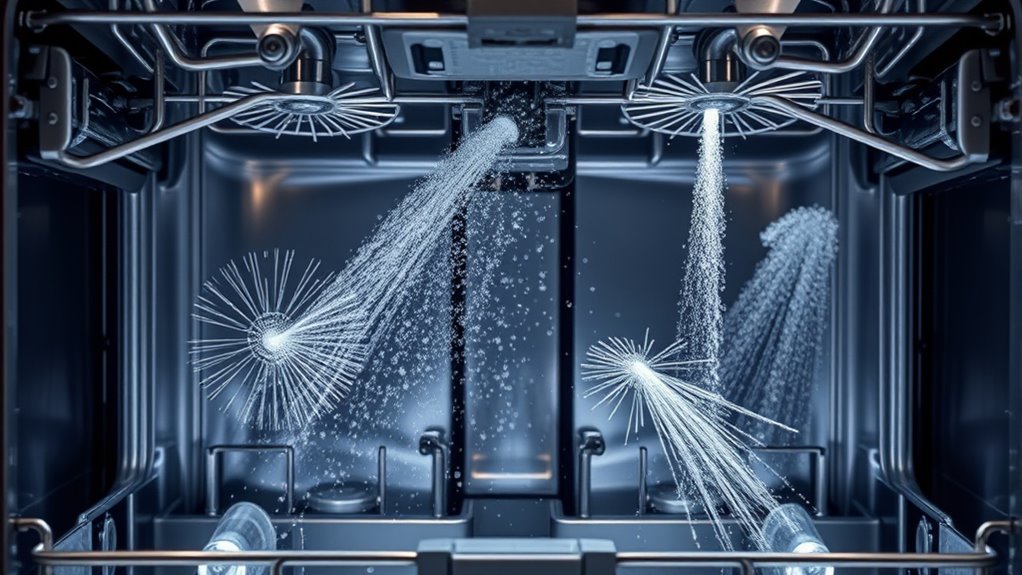

Types of Pumps Used in Dishwasher Systems

Dishwasher systems utilize various types of pumps to move water efficiently during cleaning cycles. Reversible pumps, installed vertically, can switch motor direction to alternate between washing and draining without extra motors. They connect to four-wire motors, supporting flexible water flow patterns that boost cleaning performance. In contrast, direct-drive pumps are mounted horizontally and run with motors in a single, constant direction. They use solenoids to control valves, making wiring simpler with just two wires. Circulation pumps operate continuously, drawing water from the tub and pressurizing it to ensure effective spray arm operation. They are essential for thorough cleaning, and failures can cause leaks or poor water flow. Both axial and radial pumps are common, with axial pumps being quieter, while centrifugal (radial) pumps are widely used for their pressure and flow capabilities. Additionally, the choice of pump type can influence the efficiency of water circulation and overall performance of the dishwasher. Incorporating advanced pump designs can further optimize cleaning effectiveness and energy efficiency.

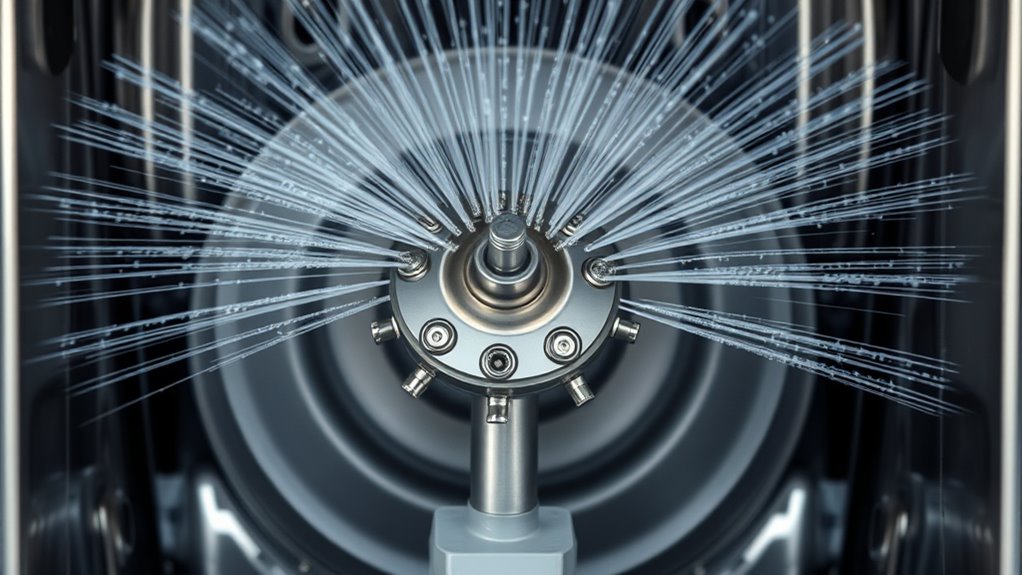

Key Features of Centrifugal Pumps in Dishwashers

Centrifugal pumps operate on a straightforward yet effective principle: a high-speed impeller spins to generate pressure by centrifugal force, pushing water through the system. Usually positioned at the bottom of the dishwasher tank below the lower spray arm, they ensure efficient water circulation. Their rapid impeller rotation forces water through spray arm holes, supporting effective cleaning. Designed for continuous operation in wet environments, they handle temperatures from -40 to 125°C. Modern models use brushless DC motors rated at 12V or 24V for durability and performance. They deliver flow rates between 35 to 60 liters per minute and static heads up to 9 meters, overcoming system resistance. These pumps optimize hydraulic performance, balancing flow, pressure, and turbulence to enhance wash results while maintaining energy efficiency and durability. They are also designed with corrosion-resistant materials to withstand prolonged exposure to water and detergents, ensuring longevity and consistent operation. Additionally, understanding hydraulic efficiency helps in selecting the most suitable pump for specific dishwasher models and cleaning requirements. Furthermore, advances in pump technology contribute to improved reliability and quieter operation in modern dishwashers.

Innovations in Pump Design for Enhanced Cleaning Efficiency

Innovations in pump design have considerably boosted cleaning efficiency by enabling more precise control over water flow and pressure. Advanced variable-speed pump motors, using ECMs with adjustable drives, tailor flow rates to each cycle phase, reducing energy use and noise while extending pump life. Pipeline-free or integrated pump designs streamline internal water paths, lowering restrictions, water consumption, and maintenance needs. Thermoelectric heat pump integration recycles heat energy, cutting energy use by about 20% and boosting drying performance by up to 60%. These developments collectively elevate dishwasher cleaning effectiveness and sustainability. Incorporating mother-baby safety features in pump systems can further enhance reliability and user confidence. Additionally, implementing innovative pump technologies can lead to quieter operation and longer-lasting components, providing a better user experience.

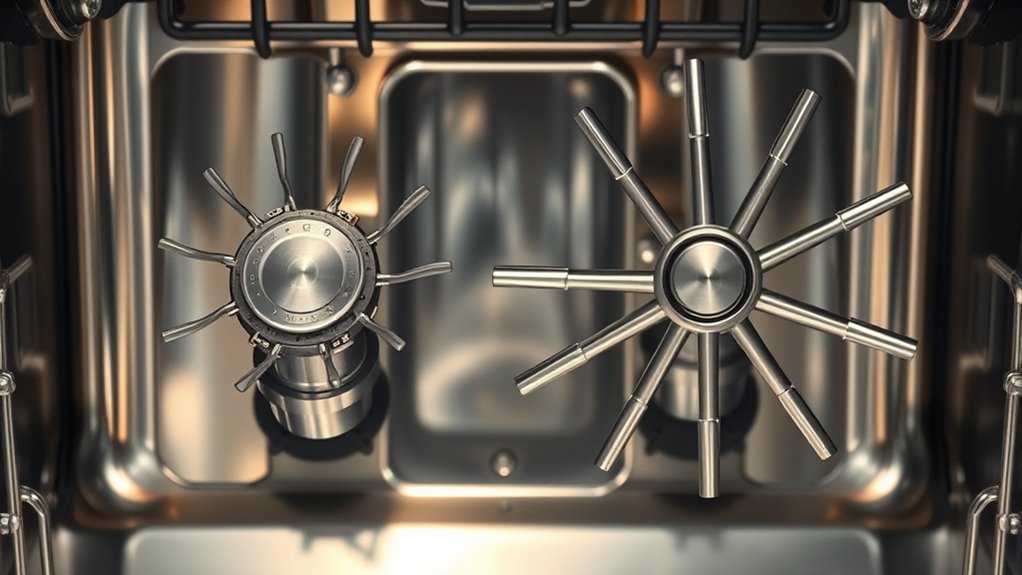

Spray Arm Configurations and Their Impact on Coverage

Have you ever wondered how spray arm placement and design influence the cleaning results in your dishwasher? Your dishwasher’s spray arms are key in distributing water efficiently. The lower spray arm, located beneath the bottom rack, ensures even coverage for dishes on the bottom. The middle spray arm targets the middle rack, while the upper arm covers the top load. Some models use alternating operation, which maintains water pressure by activating spray arms sequentially. Unique designs, like Bosch’s PowerControl Spray Arm, improve cleaning through specialized nozzles and rotating elements. Proper placement minimizes blind spots and guarantees water reaches all dishes. The angle, height, and nozzle orientation directly affect coverage, while debris buildup can clog spray arms, reducing effectiveness. Effective design and placement optimize cleaning and dish coverage during each cycle. Regular maintenance and proper placement of spray arms can significantly enhance dishwasher performance. Additionally, understanding hydraulic principles can help troubleshoot and improve spray arm function for better cleaning results.

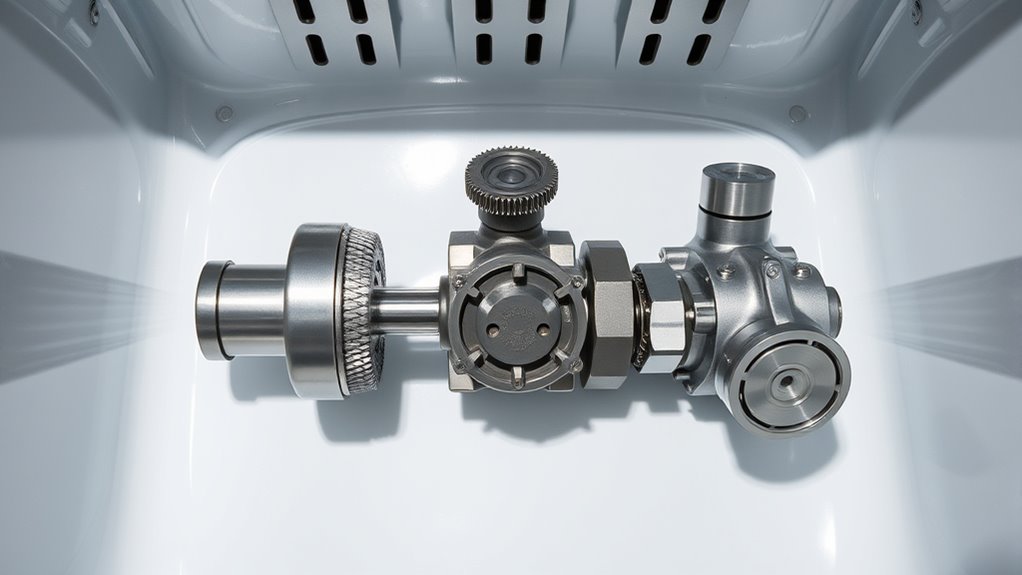

Components and Performance Factors in Dishwasher Hydraulics

The performance of your dishwasher’s hydraulic system hinges on key components like the circulation pump and flow control devices, which work together to guarantee water is delivered effectively to the spray arms. The centrifugal pump, driven by an electric motor, pressurizes water, with performance curves showing how pressure drops as flow increases. Flow control elements, like diverters and control valves, direct water to specific spray arms, optimizing cleaning. Properly designed hydraulic pathways ensure minimal pressure loss and uniform coverage.

| Component | Function | Critical Aspects |

|---|---|---|

| Circulation Pump | Pressurizes water for spray delivery | Flow rate, pressure, efficiency |

| Diverter | Routes water to selected spray arms | Flow regulation, responsiveness |

| Hydraulic Tubing | Transports water through system | Minimal pressure loss, durability |

| Filters | Remove debris, protect system components | Cleanliness, clog prevention |

| Control Valves | Direct water flow based on cycle needs | Precise operation, reliability |

Frequently Asked Questions

How Does Water Pressure Affect Cleaning Performance?

Water pressure directly impacts your dishwasher’s cleaning performance by ensuring proper spray arm rotation and forceful water jets. When pressure is too low, spray coverage decreases, food particles stay stuck, and dishes may need extra cycles or manual cleaning. Adequate pressure, ideally between 50-60 PSI, guarantees thorough rinsing, full drum filling, and effective detergent dispersion, leading to sparkling, spotless dishes every time.

What Maintenance Is Required for Dishwasher Pumps?

You need to regularly inspect and clean your dishwasher pump to keep it running smoothly. Locate the pump at the bottom, remove the filter, and clean it with soap and a soft brush. Check the impeller for debris or obstructions, and clear any buildup or foreign objects. Monthly cleaning cycles, weekly hose inspections, and replacing worn parts when necessary help prevent failures and guarantee ideal water flow and drainage.

Can Pump Design Changes Reduce Energy Consumption?

Yes, pump design changes can cut your energy use considerably. Modern pumps with improved hydrodynamics, heat recovery, and hybrid systems recycle heat and reduce electrical load. Variable speed controls and optimized spray patterns target water flow efficiently, saving power. Quieter, durable thermoelectric technologies also lower mechanical losses, while compliance with energy standards ensures your dishwasher uses less energy overall, helping you save on utility bills and reduce environmental impact.

How Are Spray Patterns Adjusted for Different Load Types?

You can adjust spray patterns by loading dishes correctly, ensuring items face inward for ideal water contact. Use flexible racks to position loads based on size and shape, avoiding overcrowding that hampers spray rotation. Sensors detect soil levels and load distribution, automatically modifying spray intensity and direction. Properly arranged dishes, like separating utensils and angling plates, help the spray arms deliver targeted water jets, improving cleaning efficiency for different load types.

What Materials Are Used to Prevent Pump Corrosion?

You prevent pump corrosion by using materials like ceramic coatings with silicon carbide and aluminum oxide, which create a strong barrier against chemicals and wear. Vinyl ester and composite coatings protect steel surfaces from long-term chemical attack. Sacrificial anodes, such as zinc and magnesium, provide galvanic protection. Additionally, specialized polymer and ceramic coatings, like Belzona products, reduce erosion and corrosion, ensuring your pump stays durable and efficient in harsh environments.

Conclusion

Think of your dishwasher as a well-orchestrated symphony, where each pump and spray pattern plays a crucial role in harmony. When you understand these hydraulic components, you’re tuning the instrument for perfect cleanliness. Just as a conductor guides the music to reach every corner, your choice of pump and spray design ensures every dish shines. Embrace these innovations, and watch your dishwasher transform into a powerhouse of spotless performance.