Recent advances in material science have led to the development of innovative oven insulation options. You’ll find ultra-lightweight aerogels, eco-friendly bio-based foams, and high-performance composites that deliver superior thermal resistance, durability, and safety. Nanotechnology enhances water resistance and extends lifespan. These breakthroughs promise more efficient, sustainable, and long-lasting insulation solutions. Keep exploring to discover how these cutting-edge materials are shaping the future of oven insulation and performance.

Key Takeaways

- Development of aerogels and ceramic composites with microscopic structures for superior thermal insulation and durability at high temperatures.

- Integration of nanotechnology to enhance water resistance, thermal stability, and long-term performance of oven insulation materials.

- Use of eco-friendly, bio-based, and recycled materials like cellulose, bamboo fiber, and glass to create sustainable insulation solutions.

- Advanced composites combining lightweight materials with high-performance reinforcements for improved impact resistance and fire safety.

- Focus on smart, self-healing, and recyclable insulation systems driven by nanostructured materials and innovative manufacturing techniques.

Emerging Materials for Superior Thermal Resistance

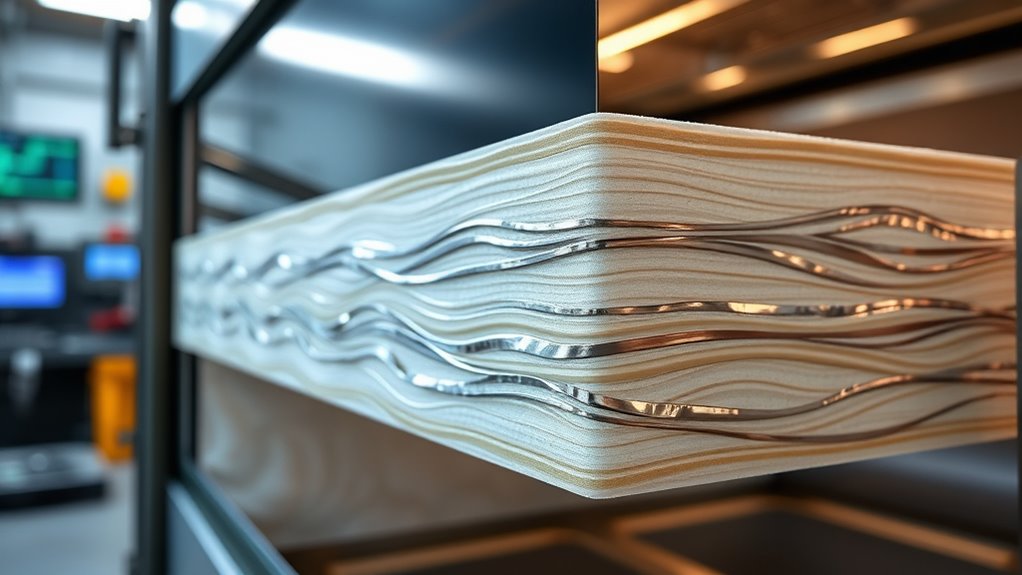

Have you ever wondered how new materials can withstand extreme heat better than traditional options? Researchers are developing advanced materials that push the limits of thermal resistance. These emerging substances often feature unique structures at the microscopic level, such as aerogels or ceramic composites, which trap air or other insulative gases. They reduce heat transfer by blocking conduction, convection, and radiation more effectively than older materials. Some of these innovations are lightweight yet incredibly durable, making them ideal for high-temperature applications. You’ll find these materials in industries like aerospace, energy, and manufacturing, where controlling heat is critical. As scientists continue to refine these substances, expect even more efficient and resilient options to replace conventional insulators, enhancing safety and performance. Advances in insulation materials are driving the development of lighter, stronger, and more heat-resistant substances across various high-tech industries. Additionally, ongoing research into material science advances is opening new avenues for creating superior thermal barriers that can withstand more extreme conditions. For example, researchers are exploring nanostructured materials, which can significantly boost thermal performance. Moreover, understanding the key metrics used to measure success in developing these materials helps guide innovation and application. Furthermore, innovations in manufacturing techniques are enabling the production of these advanced materials at scale, making them more accessible for commercial use.

Innovations in Aerogel-Based Insulation Technologies

Innovations in aerogel-based insulation technologies are transforming how industries manage extreme temperatures. Aerogels, known for their exceptional insulating properties, are now being engineered with enhanced durability and flexibility. Recent developments include composite aerogels that combine silica with polymers or carbon, boosting strength without sacrificing insulation efficiency. Spray-on aerogel coatings allow for seamless application on complex surfaces, reducing installation time and gaps that compromise insulation. Advances in manufacturing methods, such as supercritical drying and sol-gel processes, improve production scalability and cost-effectiveness. You can now incorporate lightweight aerogel panels into ovens, markedly reducing energy consumption. These innovations also enable better resistance to moisture and mechanical stress, ensuring long-term performance. As a result, aerogel technologies are setting new standards for high-performance, energy-efficient oven insulation solutions.

Development of Eco-Friendly and Sustainable Insulators

As the demand for sustainable solutions grows, developing eco-friendly and sustainable insulators becomes more crucial than ever. You can now choose materials derived from renewable sources, like bamboo fiber or cellulose, which offer excellent thermal insulation while reducing environmental impact. Researchers are creating bio-based foams from plant-based polymers that biodegrade naturally, minimizing waste. Recycled materials, such as glass or rubber, are also gaining popularity for insulation applications. These options help lower the carbon footprint of oven manufacturing and operation. Additionally, advancements in natural fiber composites provide durable, eco-conscious alternatives without sacrificing performance. Incorporating biodegradable materials into insulation design further enhances environmental benefits and supports a circular economy. Using sustainable manufacturing practices can also reduce overall environmental impact during production. By prioritizing sustainability, you contribute to reducing resource depletion and pollution, making oven insulation safer for the planet while maintaining efficiency. This shift underscores the importance of balancing performance with environmental responsibility. Moreover, innovative material science techniques enable the development of insulators that meet both environmental and industrial standards more effectively. Incorporating renewable resources into material development not only improves sustainability but also encourages the adoption of greener manufacturing practices.

Enhancing Durability and Safety With Advanced Composites

Advanced composites are transforming the durability and safety of materials by combining lightweight base materials with high-performance reinforcements. These composites offer superior strength, impact resistance, and thermal stability, making them ideal for oven insulation. By integrating fibers like carbon or glass into polymer matrices, you get materials that withstand extreme temperatures and mechanical stresses better than traditional options. This integration not only enhances material properties but also allows for customized performance tailored to specific operational needs. This means your insulation panels won’t crack or degrade easily over time, reducing maintenance costs and downtime. Additionally, advanced composites enhance safety by providing better fire resistance and reducing the risk of material failure. Their durability ensures consistent performance, even under harsh operating conditions. Incorporating these composites into oven insulation systems can also contribute to energy efficiency, leading to cost savings and environmental benefits. Moreover, ongoing innovations in composite manufacturing techniques continue to improve their cost-effectiveness, making them more accessible for various industrial applications. Overall, incorporating these composites into oven insulation systems considerably boosts longevity and safety, giving you peace of mind and improved operational reliability.

Nanotechnology’s Role in Next-Generation Oven Insulation

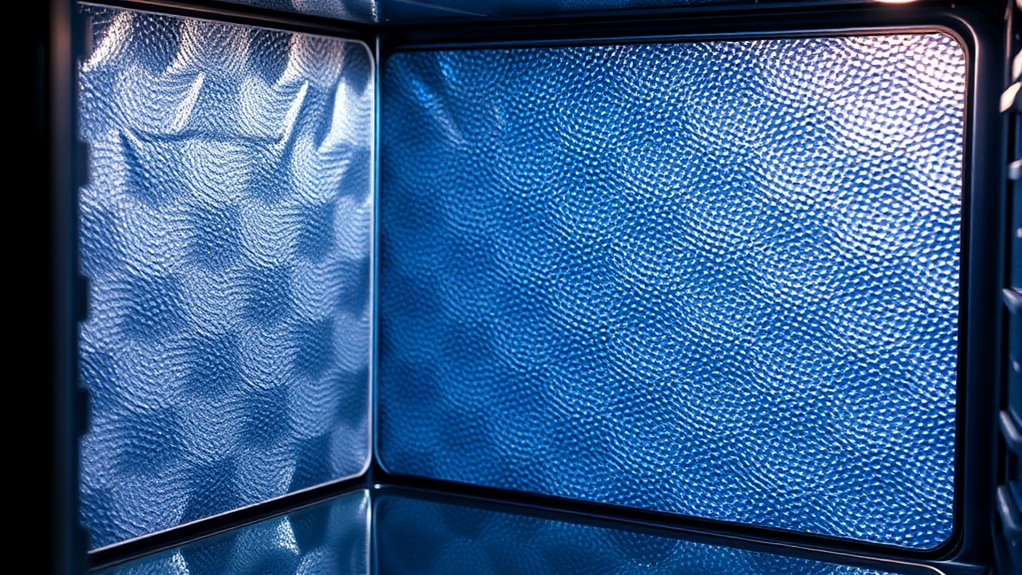

Nanotechnology improves oven insulation by considerably boosting thermal resistance, helping your appliances stay energy-efficient. It also enhances material stability, ensuring the insulation lasts longer under high temperatures. These advances could transform how you design and use oven systems in the future. Additionally, understanding material vulnerabilities allows engineers to develop more robust insulation solutions that can withstand harsh conditions. Recognizing potential risks associated with new insulation materials enables better risk mitigation strategies. As the industry continues to evolve, the integration of advanced manufacturing techniques promises even greater performance and durability in oven insulation materials. Incorporating material-specific innovations driven by nanotechnology can lead to more tailored and effective insulation solutions. Moreover, exploring water resistance properties of nanomaterials can further improve the longevity and reliability of oven insulations in various environments.

Enhanced Thermal Resistance

Have you ever wondered how next-generation oven insulation can withstand intense heat while saving energy? The key lies in enhanced thermal resistance achieved through nanotechnology. Engineers embed nanoparticles into insulation materials, creating a barrier that drastically slows heat transfer. These tiny particles increase the material’s effectiveness without adding bulk, maintaining a lightweight profile. By disrupting heat conduction at a microscopic level, nanostructures improve insulation performance. This means your ovens stay hotter with less energy, reducing costs and environmental impact. additionally, the nanomaterials are engineered to endure high temperatures without degrading, ensuring long-lasting insulation. As a result, advanced nanotechnology-enhanced insulations offer superior thermal resistance, making them essential for energy-efficient, durable oven systems in modern material science.

Improved Material Stability

Building on the improved thermal resistance achieved through nanotechnology, recent innovations focus on enhancing material stability under extreme conditions. You’ll find that next-generation oven insulations now resist high temperatures, corrosion, and mechanical stress better than ever. Nanomaterials, such as silica aerogels and carbon nanotubes, strengthen the matrix, preventing degradation over time. These advances ensure your insulation maintains its performance during rapid temperature fluctuations and harsh environments. To illustrate, consider this table:

| Material Type | Key Stability Feature |

|---|---|

| Silica Aerogels | Resistance to moisture and thermal cycling |

| Carbon Nanotubes | Mechanical strength and flexibility |

| Ceramic Composites | High-temperature durability |

These improvements mean your oven insulation will last longer, perform reliably, and withstand extreme operational demands.

Future Trends and Challenges in Material Science for Ovens

As the demand for more efficient and durable ovens grows, material scientists are focusing on developing innovative materials that can withstand higher temperatures and more aggressive environments. Future trends include lightweight, high-performance composites and nanomaterials that offer superior insulation with less bulk. Challenges involve balancing cost, manufacturability, and environmental impact while pushing material limits. You’ll see a focus on sustainable, recyclable materials that maintain performance over time. Additionally, advancements in smart materials that adapt to temperature changes could revolutionize oven insulation. To stay ahead, you should watch for these developments:

Innovative high-performance, recyclable, and smart insulation materials are shaping the future of oven durability and efficiency.

- Development of nanostructured insulators

- Integration of self-healing materials

- Use of environmentally friendly, recyclable products

- Adoption of smart, adaptive insulation systems

Frequently Asked Questions

How Do Cost Considerations Influence Material Choices for Oven Insulation?

Cost considerations substantially influence your material choices for oven insulation. You evaluate initial expenses, balancing them against long-term savings from energy efficiency. Lower-cost materials might seem appealing but could compromise insulation performance, leading to higher operational costs. Conversely, investing in advanced, more effective insulators can reduce energy consumption over time. Ultimately, you aim for a cost-effective solution that maximizes insulation benefits without exceeding your budget constraints.

What Are the Environmental Impacts of Producing Advanced Insulating Materials?

When you consider producing advanced insulating materials, you should be aware of their environmental impacts. Manufacturing often involves energy-intensive processes and the use of chemicals that can emit greenhouse gases or generate waste. These materials may also contain non-biodegradable components, contributing to pollution if not properly managed. To minimize environmental harm, you can focus on sustainable sourcing, efficient production methods, and recycling options for these high-performance insulators.

How Do Insulation Materials Perform Under Extreme Temperature Fluctuations?

You might wonder how insulation materials handle extreme temperature fluctuations. They perform well when designed with advanced materials that adapt quickly, maintaining their insulating properties despite rapid changes. These materials often have low thermal conductivity, so they resist heat transfer even in harsh conditions. When you choose high-quality insulation, it guarantees your oven stays efficient and safe, reducing energy loss and preventing damage caused by temperature swings.

Are There Any Health or Safety Risks Associated With Nanomaterials in Insulation?

When considering nanomaterials in insulation, you should be aware of potential health and safety risks. These tiny particles can become airborne during manufacturing or installation, possibly inhaled or ingested, leading to respiratory or other health issues. To protect yourself, always use proper protective gear and guarantee good ventilation. Manufacturers are working on safer nanomaterial handling protocols, but staying informed and cautious remains essential for your safety.

What Is the Lifecycle and Recyclability of New Insulation Technologies?

Think of insulation technology as a storybook that you’re just starting to read. The lifecycle of new insulation materials depends on their durability and how they’re disposed of or repurposed at end-of-life. Many advancements aim for recyclability, reducing waste like a well-oiled machine. You can expect these innovations to become more sustainable, allowing you to enjoy energy savings while minimizing environmental impact, much like turning a new page toward greener living.

Conclusion

Imagine upgrading your oven’s insulation like wrapping it in a superhero’s cape—protecting it from heat loss and boosting efficiency. Advances in materials, from aerogels to nanotech, are making this possible. Just as a well-made suit withstands storms, these innovations guarantee your oven stays safer, more durable, and eco-friendly. Embrace these breakthroughs, and you’ll turn your kitchen into a fortress of thermal excellence, ready to face any culinary challenge with confidence.