Variable-speed compressors adjust their motor speed based on your system’s actual cooling or heating needs, rather than constantly turning on and off. By matching capacity to demand, they use less energy during low loads and operate more efficiently at partial speeds. This precise control reduces waste, lowers utility bills, and minimizes environmental impact. If you want to understand how this technology can save you energy in detail, keep exploring its benefits.

Key Takeaways

- They adjust motor speed to match demand, avoiding unnecessary energy consumption during partial load conditions.

- Operating at variable speeds reduces frequent on/off cycling, decreasing energy waste and mechanical stress.

- Precise modulation maintains consistent temperatures, preventing overshoot and reducing energy used for temperature corrections.

- Optimizing compressor speed limits peak power use, lowering electrical surges and improving overall energy efficiency.

- They operate efficiently across a range of loads, leading to lower utility bills and reduced environmental impact.

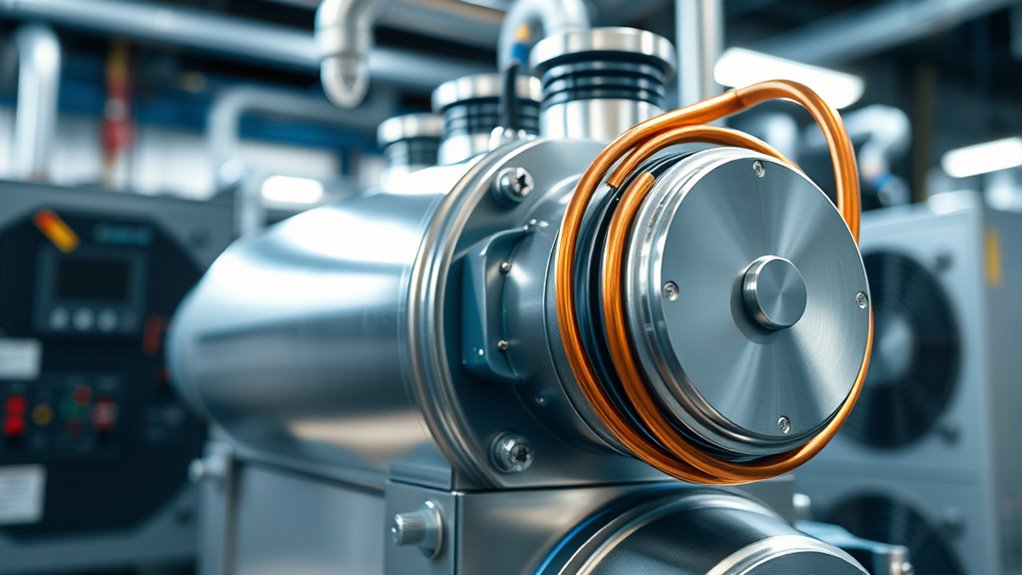

Understanding the Basics of Variable-Speed Compressors

Variable-speed compressors adjust their motor speed to match the cooling or heating demand, unlike traditional fixed-speed models that run at a constant rate. This means the compressor can operate at different speeds, providing only the amount of cooling or heating needed at any given time. As a result, it avoids the energy waste caused by constantly turning on and off or running at full capacity. Instead, the compressor modulates its output smoothly, maintaining a more consistent temperature. This flexibility allows for better efficiency because it minimizes unnecessary energy consumption. You’ll notice that your system runs quieter and more steadily with a variable-speed compressor. Recognizing patterns of behavior in system operation can help optimize performance and further enhance energy savings. Additionally, these systems can adapt to changes in environmental conditions, further improving their energy efficiency.

How Variable-Speed Compressors Adjust to Demand

Variable-speed compressors adjust their speed based on real-time demand, ensuring ideal performance. By modulating the compressor’s speed, they respond quickly to changing conditions, avoiding unnecessary energy use. This approach promotes energy-efficient operation and helps you save on energy costs. Additionally, advancements in AI-powered solutions continue to optimize these systems for even greater efficiency, leading to smarter home and industrial systems that adapt seamlessly to varying needs.

Modulating Compressor Speed

Have you ever wondered how modern compressors efficiently match their output to fluctuating cooling or heating demands? Variable-speed compressors modulate their speed to meet these changing needs precisely. Instead of cycling on and off, they adjust their motor speed, maintaining consistent temperature levels and reducing energy waste. This precise control minimizes sudden power surges and enhances system stability. Additionally, energy consumption varies depending on the compressor’s speed, allowing for optimized operation. This adaptive functionality is a key feature of the best heat pump systems, contributing to their superior efficiency. Here’s a quick look at how different speeds impact performance:

| Speed Level | Output Capacity | Energy Efficiency |

|---|---|---|

| Low | 30% | High |

| Medium | 60% | Very High |

| High | 100% | Ideal |

| Overdrive | 110% | Less Efficient |

| Idle | 0% | No Power Use |

Furthermore, variable-speed technology plays a vital role in reducing overall energy consumption by adjusting to real-time demand. Understanding the modulation process can help optimize the efficiency of HVAC systems. Additionally, incorporating renewable energy sources into the power supply can further enhance the environmental benefits of these systems.

Real-Time Demand Response

Ever wonder how compressors instantly adjust their output to match changing demand? With variable-speed technology, they respond in real time by continuously monitoring system needs. Sensors detect fluctuations in temperature, pressure, or airflow, then communicate with the compressor’s controller. The controller quickly adjusts the motor speed, increasing or decreasing capacity as needed. This dynamic response prevents over- or under-compression, maintaining ideal system performance. Unlike traditional compressors that run at fixed speeds, variable-speed units adapt instantly, reducing energy waste from unnecessary operation. This real-time demand response ensures your system operates efficiently regardless of load variations, saving energy and reducing operational costs. It also minimizes wear and tear, extending equipment life while keeping your environment comfortable and stable.

Energy-efficient Operation

Because these compressors adjust their speed in real time, they optimize energy use by matching output precisely to demand. This means you avoid unnecessary power consumption during low-demand periods, reducing waste and lowering your energy bills. Variable-speed operation allows the compressor to operate at the most efficient point for the current load. To maximize benefits, consider these key factors: 1. Precise control: Keeps energy use aligned with actual needs, preventing overshooting. 2. Reduced wear and tear: Smoother operation extends equipment lifespan. 3. Lower operational costs**: Less energy consumption translates into significant savings over time. Additionally, implementing GMC tuning techniques can further improve system efficiency by optimizing engine performance to match operational demands. Incorporating AI-driven monitoring can also help continuously optimize compressor performance for maximum energy savings, ensuring adaptive responses to changing conditions and maintaining energy efficiency. Moreover, regular maintenance of components ensures consistent performance optimization**, which is crucial for maintaining energy-efficient operation.

The Role of Inverter Technology in Energy Efficiency

Inverter technology plays a key role in making variable-speed compressors more energy-efficient by controlling the motor speed precisely. This allows you to maintain a consistent temperature without wasting energy, even as conditions change. As a result, you save power and reduce your overall energy costs. Additionally, modern inverter systems often incorporate energy-saving features that optimize performance further. These innovative systems also foster a community-driven platform of continuous improvement and shared expertise, which can lead to ongoing innovations in compressor efficiency and reliability. Furthermore, integrating advanced control systems can enhance how these compressors adapt to varying demands, maximizing energy savings.

Inverter Speed Control

Inverter technology plays a crucial role in enhancing the energy efficiency of variable-speed compressors by adjusting their motor speed to match demand. This means the compressor doesn’t run at full capacity all the time but instead modulates its speed to meet actual cooling or heating needs. This precise control reduces unnecessary power consumption, saving energy and lowering costs. Here are three key benefits of inverter speed control:

- Optimized performance – keeps the system running smoothly without abrupt starts or stops.

- Lower energy waste – minimizes power use during low demand periods.

- Extended equipment lifespan – reduces wear and tear on compressor components.

Precise Temperature Regulation

By continuously adjusting motor speed, inverter technology allows variable-speed compressors to maintain precise temperature control. Instead of turning on and off repeatedly, the compressor modulates its power output to match the cooling or heating demand exactly. This rapid, fine-tuned adjustment prevents temperature fluctuations, keeping indoor environments consistently comfortable. You benefit from more stable temperatures without sudden changes or overshoots. This level of control enhances comfort and reduces the need for additional heating or cooling cycles. As a result, your system operates more smoothly and efficiently. Precise regulation also minimizes wear on components, extending the lifespan of your equipment. Overall, inverter technology guarantees your climate is maintained accurately while optimizing energy use.

Reduced Energy Waste

Because the compressor adjusts its speed to match the exact heating or cooling demand, it avoids the energy losses associated with traditional on/off systems. This means you waste less energy, making your system more efficient. Inverter technology enables this precise control, reducing unnecessary power consumption.

To understand its impact:

- It minimizes energy spikes during startup, saving power.

- It maintains consistent temperatures without overworking the system.

- It lowers overall energy bills by operating only at needed capacities.

Comparing Fixed-Speed and Variable-Speed Systems

When choosing between fixed-speed and variable-speed systems, understanding their fundamental differences can help you make an informed decision. Fixed-speed compressors run at a constant speed, turning on or off as needed, which can lead to energy waste. Variable-speed compressors adjust their motor speed to match demand, saving energy and maintaining consistent performance. To visualize:

| Feature | Fixed-Speed System | Variable-Speed System |

|---|---|---|

| Operation | On/Off | Continuous, adjustable |

| Energy Efficiency | Lower during partial load | Higher, adapts to demand |

| Cost | Lower initial cost | Higher upfront investment |

This comparison highlights how variable-speed systems optimize energy use by matching compressor output to actual needs.

Impact on Power Consumption During Different Operating Conditions

Variable-speed compressors adjust their speed based on demand, helping you save energy during varying loads. They also reduce peak power draw, preventing spikes that can strain your system. As a result, they operate more efficiently across different conditions, lowering your overall energy costs.

Adaptive Speed Adjustment

Adaptive speed adjustment allows variable-speed compressors to modify their operating speed in real-time, maximizing energy use based on current cooling or heating demands. By continuously adjusting speed, the compressor avoids unnecessary energy consumption during partial loads or low-demand periods. This flexibility ensures the system operates at just the right capacity, reducing waste.

Consider these benefits:

- Improved Efficiency – Matching output to demand cuts down on excess energy use.

- Consistent Comfort – Maintains stable temperatures without sudden fluctuations.

- Lower Operating Costs – Reduced energy consumption translates to savings on utility bills.

This dynamic adjustment means your system uses only the energy needed, improving overall efficiency and reducing environmental impact. Adaptive speed adjustment ensures you get ideal performance with minimal waste.

Reduced Peak Power Draw

Reduced peak power draw is a key advantage of variable-speed compressors, especially during start-up and high-demand periods. Unlike traditional compressors that spike power consumption at startup, these compressors gradually ramp up their speed, smoothing out power demands. This controlled acceleration prevents sudden electrical surges, reducing stress on your electrical system and lowering initial energy costs. During peak demand times, the compressor adjusts its speed to match the load, avoiding unnecessary power consumption. As a result, you experience less strain on your electrical infrastructure and more stable energy use. This ability to limit peak power draw not only cuts energy bills but also extends equipment lifespan by reducing electrical and mechanical stress. Overall, variable-speed technology helps your system operate more efficiently and reliably during fluctuating load conditions.

Efficiency at Varying Loads

Because compressors frequently operate under varying load conditions, their ability to adjust speed directly impacts power consumption. When a compressor can match its output to real-time demand, it uses less energy during lower loads and avoids unnecessary wear during peak periods. This adaptability improves overall efficiency, especially in fluctuating environments. Here are three key points to take into account:

- Optimal Energy Use: Variable-speed units consume less power when demand drops, reducing waste.

- Reduced Wear and Tear: Smoother adjustments prevent stress on components, extending lifespan.

- Consistent Performance: Maintaining efficiency across different loads ensures reliable operation and lower operating costs.

How Variable Speed Reduces Wear and Extends Equipment Life

Variable speed compressors adjust their motor speed to match the demand, which means they don’t cycle on and off as frequently as traditional fixed-speed units. This steady operation reduces stress on components caused by frequent start-stop cycles, decreasing wear and tear. When a compressor runs constantly at a lower, optimized speed, it experiences less mechanical strain, extending its lifespan. Additionally, variable speed units avoid sudden pressure changes that can damage internal parts over time. The smoother operation minimizes vibrations and reduces the likelihood of component fatigue. Overall, this means you enjoy more reliable performance and fewer repairs. By reducing unnecessary cycling and mechanical stress, variable speed compressors considerably prolong equipment life, saving you money on maintenance and replacements in the long run.

The Influence of Load Fluctuations on Compressor Performance

Load fluctuations considerably impact compressor performance by causing variations in pressure and flow rates. When demand spikes or drops unexpectedly, your compressor must quickly adapt, which can lead to inefficiencies and increased wear. Variable-speed compressors respond smoothly to these changes, maintaining ideal operation.

Here are three key points to contemplate:

- Rapid adjustments prevent pressure drops, ensuring consistent output.

- Fluctuating loads can cause frequent cycling in fixed-speed units, reducing lifespan.

- Smooth modulation in variable-speed models minimizes stress and energy waste during demand changes.

Benefits of Precise Control in Energy Savings

Precise control in variable-speed compressors directly translates to significant energy savings. When your system adjusts motor speed accurately to match demand, it avoids wasting energy running at full capacity when it’s not needed. This means the compressor operates more efficiently, using only the power required for current conditions. By maintaining ideal pressure and flow, you reduce unnecessary cycling and energy spikes. The ability to fine-tune performance minimizes idle times and prevents over-compression, which consumes extra power. As a result, your system stays balanced and responsive, ensuring energy is not wasted on excessive operation. This level of control not only cuts energy bills but also extends equipment lifespan by reducing wear and tear caused by constant on-off cycling.

Cost Savings Over Time With Variable-Speed Compressors

Over time, investing in variable-speed compressors can lead to substantial cost savings. These systems adapt to your actual demand, reducing unnecessary energy consumption. As a result, you’ll see lower utility bills and decreased operational costs. To maximize savings, consider:

Investing in variable-speed compressors saves energy, reduces costs, and extends equipment life over time.

- Reduced energy bills due to precise control and less wasted power.

- Lower maintenance costs because variable-speed units experience less wear and tear.

- Extended equipment lifespan from operating under ideal conditions consistently.

Environmental Advantages of Using Variable-Speed Technology

Implementing variable-speed technology offers significant environmental benefits by reducing energy consumption and minimizing greenhouse gas emissions. When your compressor adjusts its speed to match demand, it uses less power, leading to a smaller carbon footprint. This efficiency helps fight climate change by decreasing harmful emissions. It also conserves natural resources, preserving the environment for future generations.

| Impact | Benefit |

|---|---|

| Lower energy use | Reduces pollution and conserves resources |

| Less emissions | Contributes to cleaner air and healthier planet |

| Sustainable future | Ensures a greener, more resilient environment |

Frequently Asked Questions

How Do Variable-Speed Compressors Impact Overall System Stability?

You might wonder how variable-speed compressors affect system stability. They adapt their speed to match demand, providing smoother operation and reducing short cycling. This continuous adjustment minimizes pressure fluctuations and maintains consistent system performance. As a result, your system becomes more stable, with fewer abrupt changes or shocks. Overall, variable-speed compressors enhance reliability by ensuring steady operation, which can extend equipment life and improve comfort.

Are There Specific Industries That Benefit Most From Variable-Speed Compressors?

You might notice that industries like manufacturing, data centers, and hospitals benefit the most from variable-speed compressors. These sectors require precise, consistent cooling or compression, which fluctuates with demand. Variable-speed compressors adapt quickly, maintaining stable operations while saving energy. By adjusting their output in real-time, you reduce operational costs and improve system efficiency, making them ideal for environments with variable load demands and a need for reliable performance.

What Maintenance Challenges Are Unique to Variable-Speed Compressor Systems?

Imagine you’re in a bustling factory, like it’s the 1920s, yet you’re managing modern equipment. With variable-speed compressors, you face unique maintenance challenges. You need to monitor sophisticated control systems and guarantee precise calibration of sensors. Regularly inspecting electrical components and software updates is vital. Unlike traditional compressors, you must also check variable-speed drives for wear and tear, making maintenance more complex but indispensable for peak performance.

How Quickly Can Variable-Speed Compressors Respond to Sudden Demand Changes?

When demand suddenly spikes, your variable-speed compressor responds rapidly, often within seconds to a minute, adjusting its motor speed to meet the new load. Unlike fixed-speed units, these compressors constantly monitor system needs and modulate output accordingly. This quick response minimizes energy waste, maintains system stability, and guarantees efficient operation. You benefit from improved control, reduced wear, and energy savings, especially during fluctuating demand periods.

What Are the Initial Costs Versus Long-Term Savings of Upgrading to Variable-Speed Technology?

Imagine standing at a crossroads, weighing immediate costs against future gains. Upgrading to variable‑speed compressors requires higher initial investment, but you’ll save money over time through reduced energy bills and fewer maintenance needs. The long-term savings often outweigh the upfront costs, especially as energy prices rise. Think of it as planting a seed today that grows into a more efficient, cost-effective system, rewarding you with ongoing savings and reliability.

Conclusion

So, despite the fancy tech and energy savings, don’t forget that even the smartest variable-speed compressors need your attention and maintenance. Ironically, their efficiency depends on proper use, so while they cut costs and reduce environmental impact, neglecting them could mean missing out on all those benefits. In the end, just like with anything high-tech, it’s your care that truly makes the difference—otherwise, all that energy savings might just be wasted.