To guarantee your gas range is safe, you need to check that anti-tip brackets are properly installed and secure, preventing the stove from tipping over during use. Flame-failure devices automatically shut off gas if the flame goes out, reducing fire or gas leak risks. Proper installation and maintenance are essential, and many safety features are required by law. Keep your appliance checked and maintained—there’s more to know about keeping your kitchen safe and compliant.

Key Takeaways

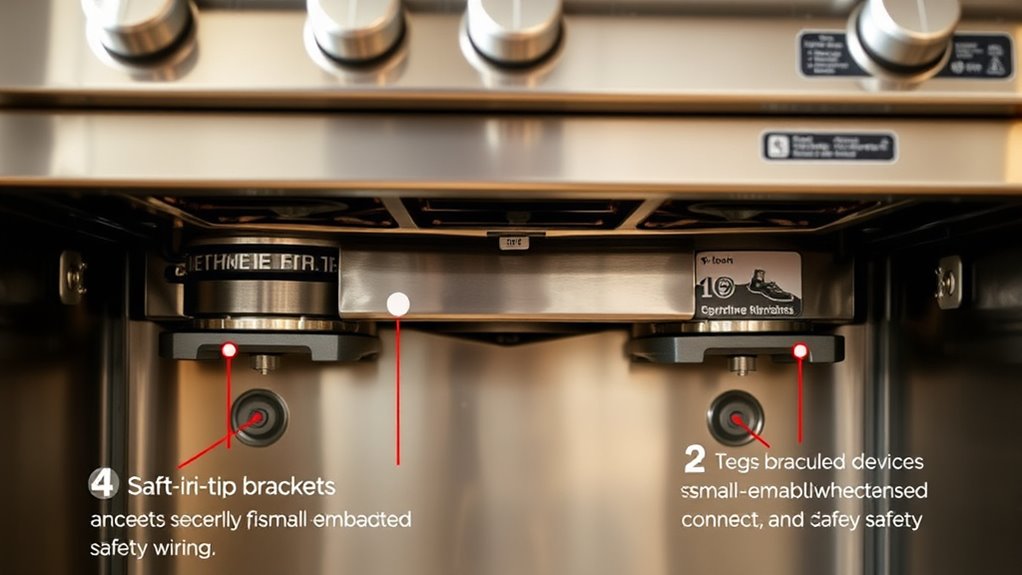

- Anti-tip brackets are mandatory safety devices that prevent gas ranges from tipping over during use.

- Proper installation of anti-tip brackets is critical to minimize tip-over injuries and ensure compliance with safety standards.

- Flame-failure devices (FFD) automatically shut off gas supply if flames extinguish, preventing gas leaks and explosions.

- Regular inspection and maintenance of safety devices, including checking brackets and thermocouples, enhance kitchen safety.

- Missing or malfunctioning safety features increase risks of injuries, fires, gas leaks, and carbon monoxide poisoning.

The Role of Anti‑Tip Brackets in Preventing Kitchen Accidents

Anti-tip brackets play a essential role in keeping your stove stable and preventing dangerous accidents in the kitchen. Without them, your range can tip forward if pressure is applied to the oven door, risking serious injuries. Safety standards by UL and ANSI require ranges made after 1991 to stay stable under 250 pounds of pressure for five minutes, making anti-tip brackets indispensable. Many ranges include brackets, but if they’re not installed properly, the risk of tip-overs increases considerably. This can lead to severe injuries or fatalities, especially among children. The Consumer Product Safety Commission estimates about 1,700 injuries and several deaths annually from range tip-overs. Installing anti-tip brackets correctly is a simple yet essential step to ensure your family’s safety and prevent avoidable accidents. Despite longstanding awareness, many retail stores and manufacturers still do not consistently provide or properly install these safety devices, leaving consumers vulnerable. Proper installation techniques are vital for ensuring the brackets function as intended and provide maximum safety. Additionally, understanding the importance of proper installation can help prevent unintended tip-overs and enhance overall kitchen safety.

How Flame‑Failure Devices Enhance Gas Range Safety

Having sturdy anti-tip brackets helps prevent accidents related to stove tipping, but gas ranges also rely on safety devices to manage the risks of gas leaks. Flame‑failure devices (FFD) are essential in this regard. They prevent the buildup of unignited gas when a flame goes out, reducing explosion risks. FFDs use thermocouples that generate voltage when heated by the flame, keeping the gas valve open. If the flame extinguishes, the thermocouple cools, causing the valve to close immediately and stop gas flow. This automatic shutoff prevents leaks and the release of harmful gases, protecting you from potential poisoning or fire hazards. Gas leak prevention is a critical aspect of these safety devices. Widely adopted worldwide, FFDs ensure safer cooking environments and help appliances meet modern safety standards. Regular testing and maintenance of FFDs are crucial to ensure their proper functioning over time.

In addition, thermocouple technology plays a vital role in detecting the presence of a flame and ensuring the safety mechanism activates promptly.

Installation Guidelines and Compliance Standards for Safety Devices

Properly following manufacturer installation instructions is essential to guarantee your safety devices work correctly. You also need to verify compliance with local codes and standards to avoid violations and hazards. Additionally, understanding bicycle maintenance can help prevent equipment failure that might compromise safety. Finally, testing safety devices after installation confirms they function properly and help prevent accidents. Regular maintenance and inspections are also vital to ensure ongoing safety and compliance over time.

Manufacturer Installation Instructions

When installing safety devices like anti-tip brackets, it’s essential to follow the manufacturer’s instructions precisely to guarantee your range remains stable and safe. Proper installation ensures compliance with safety standards and prevents accidents. Carefully read and follow all guidelines included with the device. Make sure to install brackets at the specified locations, typically about 1 inch from the range’s side, and secure them firmly with screws. Confirm that the rear foot of the range engages securely into the bracket slot, and test for proper engagement by sliding the range back. Always verify that the installation is complete and correct before use. Remember, manufacturer instructions are designed to maximize safety and efficiency, so don’t skip any steps or ignore warnings. Additionally, installation accuracy is critical for ensuring the safety features function properly and maintain compliance with safety standards. Proper adherence to installation guidelines helps prevent potential hazards and ensures the safety devices perform as intended.

Compliance With Local Codes

Ensuring your gas range installation meets local codes is essential for safety and compliance. You must follow local requirements or the National Fuel Gas Code ANSI Z223.1 if no local standards exist. Manufactured homes need to adhere to specific standards like Title 24 CFR Part 3280 or ANSI/NCSBCS A225.1. Local codes typically require qualified professionals for installation, proper clearances, correct gas line sizes, and sealed openings to prevent leaks. Safety devices like anti-tip brackets must be installed according to mounting height and anchoring instructions, with routine inspections recommended. Flame-failure devices must be correctly connected, tested, and comply with safety standards. Proper gas supply line sizing, secure connections, and leak testing are critical for compliance. Additionally, understanding portable power options can help ensure safe and reliable operation of your appliances during power outages. Ensuring adherence protects your safety and maintains your appliance’s certification.

Safety Device Testing

How do you confirm that safety devices like anti-tip brackets and flame-failure sensors are functioning correctly? You need to follow specific testing procedures and installation checks. These include simulating operating conditions, such as ignition and flame loss, to verify quick gas shutoff and flame detection. Mechanical testing ensures anti-tip brackets are securely anchored and can withstand normal use forces. Performance tests confirm devices operate reliably across varying gas pressures and environmental conditions. Proper installation, including correct mounting, alignment, and connection to control systems, is essential. You should also conduct pressure tests and ignition trials to verify correct responses. Regular inspections are necessary to ensure continued mechanical integrity and proper functioning over time. Additionally, incorporating automation technologies can help monitor device performance continuously and alert users to potential malfunctions. Utilizing standardized testing protocols ensures consistency and compliance with safety standards, providing peace of mind for users.

Recognizing Common Safety Defects and Ensuring Proper Maintenance

Recognizing common safety defects in your gas range is essential for preventing accidents and ensuring reliable operation. Inspect anti-tip brackets regularly to confirm they’re secure, preventing tipping hazards. Check flame-failure devices to ensure they shut off the gas if the flame goes out; malfunctioning units pose serious risks. Look for signs of malfunctioning ignitions, such as failure to ignite or inconsistent flames, which can cause gas buildup. Keep an eye on ventilation—poor airflow can lead to dangerous pollutant levels like carbon monoxide and nitrogen dioxide. Examine connections for leaks or corrosion, and replace worn parts promptly. Clean burners frequently to prevent blockages and ensure proper gas flow. Proper maintenance and early detection of defects help keep your gas range safe and functioning efficiently. Regularly testing safety devices and understanding their operation can further enhance your kitchen’s safety. Additionally, understanding the importance of proper ventilation can significantly reduce the risk of harmful gas accumulation.

Regulatory Requirements and Manufacturer Responsibilities

Regulatory requirements play a crucial role in guaranteeing the safety of gas ranges, with laws and standards establishing specific mandates for key safety features like anti-tip brackets and flame-failure devices. Manufacturers are required to include anti-tip brackets with all new ranges manufactured since 1988 and provide them free of charge if missing. Installation instructions must clearly guide users on proper bracket attachment, and delivery services are often mandated to install these safety devices. Regulatory agencies like the CPSC monitor compliance through inspections and injury reports. Manufacturers also have responsibilities for flame-failure devices, ensuring proper design, testing, and user instructions. Supporting replacement parts and maintenance services is essential to maintain ongoing safety and compliance. Supporting replacement parts and maintenance services are critical to ensure ongoing safety, as they help address wear and tear that could compromise safety features over time. Password strength evaluation systems and security measures are integrated into user access processes to enhance safety and protect user information.

Risks Associated With Missing Safety Features

When safety features are missing, your gas range becomes a significant hazard. Without anti-tip brackets, the stove can tip over, causing burns or injuries, especially if heavy cookware is involved. Additionally, the absence of gas leak prevention devices increases the risk of fires, explosions, and carbon monoxide poisoning. Proper installation of safety features is essential to prevent such dangers and ensure safe operation. Incorporating safety mechanisms can significantly reduce the likelihood of accidents and enhance overall kitchen safety.

Tip-over Injury Risks

Missing safety features like anti-tip brackets considerably raise the risk of gas ranges tipping over, especially when weight is applied forward, such as on an open oven door. Without these devices, heavy objects or even a child leaning on the oven can cause the appliance to fall, leading to serious injuries. These accidents often result in burns, fractures, head injuries, or trauma to the torso. Tip-overs are responsible for roughly 1,100 to 1,200 injuries annually, with children being particularly vulnerable. The absence of anti-tip brackets makes ranges unstable, increasing the chance of catastrophic incidents. To prevent these risks, verify your range has properly installed safety devices and avoid placing heavy items on open oven doors. Regular safety checks are essential for protecting everyone in your home.

Gas Leak Hazards

Without proper safety features, gas ranges can pose substantial leak and fire hazards. Missing devices like flame-failure systems or leak sensors increase the risk of undetected gas leaks, which can lead to fires or explosions. Leaking natural gas accumulates in enclosed spaces, creating highly combustible environments. If ventilation isn’t adequate, gas buildup can displace oxygen, causing asphyxiation. Regular maintenance and proper installation of safety brackets and leak detection devices are vital for reducing these risks. Inadequate safety measures also raise concerns for vulnerable populations, such as children and the elderly, who are more susceptible to harm from leaks and emissions. Installing safety features and ensuring proper ventilation greatly lower the danger of gas leaks, protecting your home and loved ones from potentially catastrophic incidents. Additionally, proper installation and maintenance of safety devices are essential to ensure they function correctly when needed. Ensuring that all safety features are in place supports a spiritually aligned approach to home safety, reinforcing protection and peace of mind.

Tips for Inspecting and Upgrading Your Gas Range Safety Systems

Regularly inspecting and upgrading your gas range’s safety systems is essential to guarantee reliable operation. Start by removing stored items and turning off all burners and oven elements. Gently grasp the stove’s upper rear panel and tilt it forward no more than 3 inches—if it tips more, the anti-tip bracket may be missing. Use a flashlight to check behind the stove for an L-shaped bracket securing it to the wall or floor.

- Remove the bottom drawer to inspect for brackets behind the stove

- Test stability by gently pressing on the oven door or stovetop

- Look for signs of corrosion, damage, or looseness in brackets

- Consult the manufacturer’s guidelines for proper upgrade or replacement kits

Frequently Asked Questions

Are Anti-Tip Brackets Required by Law for All New Gas Ranges?

Yes, anti-tip brackets are required by law for all new gas ranges. Manufacturers have included them as standard equipment since 1991, and installation follows the manufacturer’s instructions, which typically mandate their use. Building codes like the IRC and local regulations also emphasize following these instructions. When installed properly, these brackets prevent range tip-over, safeguarding your household, especially children and the elderly. Always verify that your new range includes and has the brackets correctly installed.

How Often Should Flame-Failure Devices Be Tested for Proper Operation?

You should test your flame-failure device during routine maintenance, ideally every two years, but verify your specific model’s recommendations. Regular visual inspections and functional tests help guarantee it works correctly. Always have a licensed professional perform these tests to confirm proper operation, calibration, and gas leak checks. Keeping detailed records of maintenance and testing helps maintain compliance and safety, reducing risks of gas leaks or explosions.

Can Existing Ranges Be Retrofitted With Anti-Tip Brackets or Flame-Failure Devices?

Yes, your existing range can be retrofitted with anti-tip brackets or flame-failure devices. Think of these upgrades as shields that protect your home’s foundation and peace of mind. Manufacturers like GE offer retrofit kits, often free, that are easy to install—sometimes in just minutes. For flame-failure devices, professional help may be needed to guarantee proper and safe integration. Taking these steps keeps your kitchen safe and secure.

What Are the Signs That Safety Devices on My Range May Be Malfunctioning?

If you notice your range shutting off unexpectedly, uneven flames, or difficulty igniting burners, your safety devices might be malfunctioning. Watch for strange noises, changes in flame color, or gas odors, which can also signal issues. Regularly inspect your range for visible damage or wear, and don’t dismiss these signs. Promptly contacting a professional for maintenance ensures your safety and keeps your appliances functioning correctly.

Do All Brands and Models Include These Safety Features Automatically?

Ever wonder if your range has all safety features? Not all brands and models include anti-tip brackets or flame-failure devices automatically. While newer ranges often come with these safety features, many older or budget models might lack them. You should check your specific appliance’s specifications or look behind the stove for the anti-tip bracket. If missing, contact the manufacturer for installation options or retrofit kits to guarantee your safety.

Conclusion

By ensuring your gas range is equipped with anti-tip brackets and flame-failure devices, you create a safer kitchen sanctuary. Imagine the warm glow of your stove without the threat of accidents lurking behind the scenes. Regular inspections and timely upgrades keep your family protected, transforming your cooking space into a haven of peace. Take action now—your vigilance turns everyday cooking into a safe, comforting experience, where safety is always within reach.