Vacuum sealers work by using a vacuum pump to remove air from the bag, creating a low-pressure environment that slows bacteria growth and preserves food. The heat bar then melts the plastic edges to form an airtight seal, trapping the remaining air inside. This combination extends freshness and saves space. If you want to understand how these components work together and maintain your sealer, there’s more to discover ahead.

Key Takeaways

- Vacuum pumps create a pressure difference by removing air from the chamber, maintaining a low-pressure environment for sealing.

- Heat bars contain embedded heating elements that activate when fully closed, melting thermoplastic to fuse bag edges.

- The vacuum pump evacuates air through mechanical systems like rotary vanes or pistons, ensuring an airtight environment.

- The heat bar’s sealing process typically takes around three seconds, forming a secure, airtight seal on the bag.

- Proper maintenance of both the vacuum pump and heat bar ensures consistent sealing performance and prevents malfunctions.

Components of a Vacuum Sealer

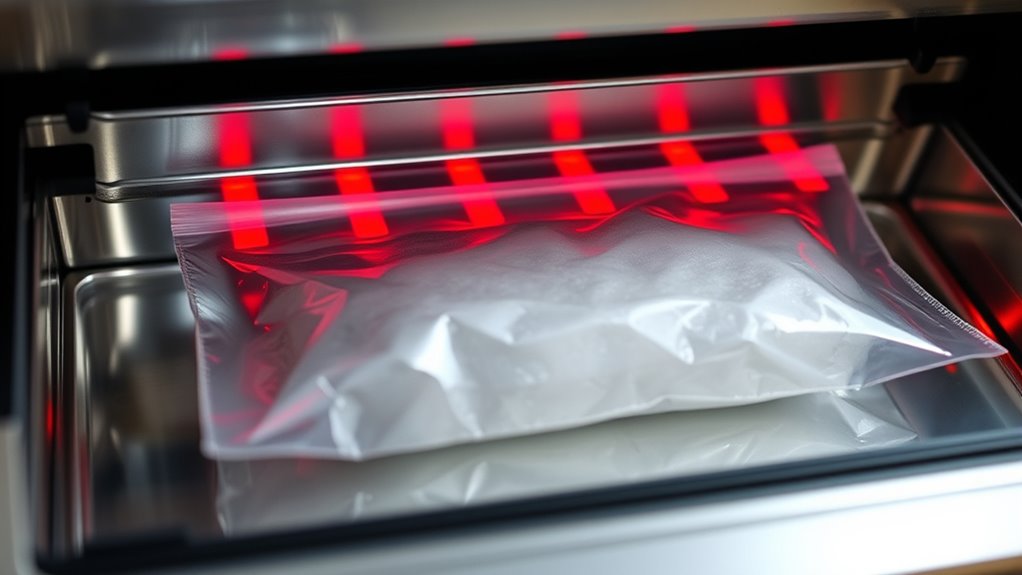

A vacuum sealer consists of several key components that work together to remove air and create a secure seal. The vacuum chamber is where the sealing happens; it’s usually top-open with a sealing strip at the bottom. This airtight chamber holds your product and packaging during the process, guaranteeing no air gets in. The sealing strip or seal bar is a heating element that fuses the packaging edges by melting the material, controlled by temperature and timing settings. The control panel acts as the user interface, allowing you to set vacuum strength, sealing temperature, and duration. Supporting parts like the frame, gaskets, and hoses keep everything stable and airtight. These components work seamlessly to ensure your packaging is airtight, secure, and ready for storage or transport. Vacuum pump is crucial for removing air effectively, creating the necessary environment for proper sealing. Additionally, the efficiency of the heat bars depends on precise temperature control to prevent over- or under-sealing. Maintaining proper component function ensures optimal performance and prolongs the lifespan of your vacuum sealer.

How Vacuum Pumps Remove Air and Create a Vacuum

Ever wondered how vacuum pumps actually remove air to create a vacuum? It all comes down to mechanical systems like rotary vanes or pistons that generate a pressure difference. These parts compress and move gases from high to low-pressure areas, pulling air out of the system. As the gases are continuously evacuated, a lower-pressure environment forms, resulting in a vacuum. Mechanical operation using rotary vanes or pistons is fundamental to this process, with pressure differential being the driving force behind air removal. Key points include:

- Mechanical operation using rotary vanes or pistons

- Gases move from high to low-pressure zones

- Continuous removal maintains vacuum

- Rotating parts like rotors help in compressing gases

- Low-pressure chambers facilitate air extraction

- Proper maintenance of the pump is essential for consistent vacuum performance, ensuring the system operates efficiently and prolongs its lifespan.

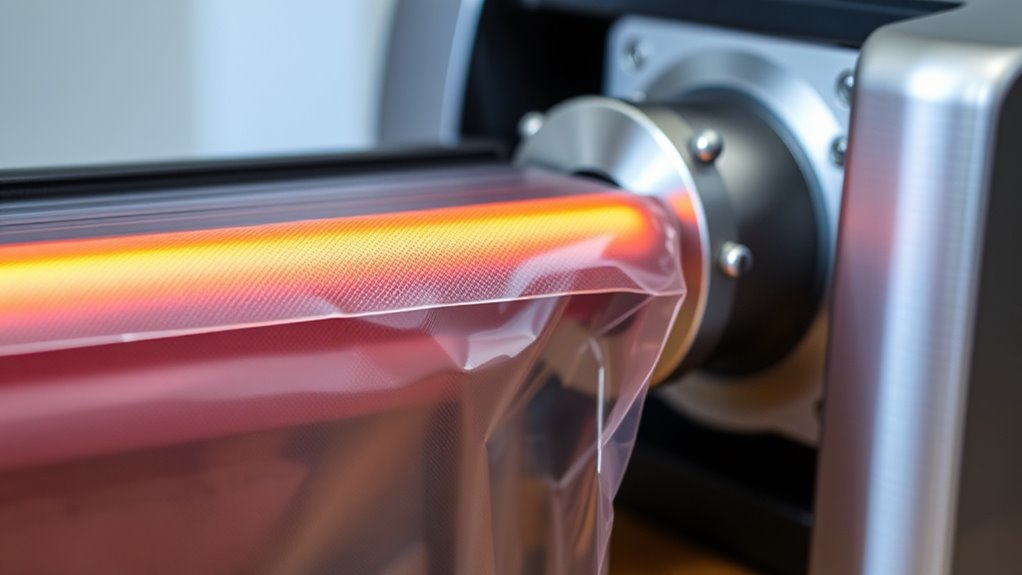

The Role of Heat Bars in Sealing Bags

Heat bars are essential components in vacuum sealers, responsible for creating a strong, airtight seal on the bags. They contain embedded heating elements that activate when pressed fully closed over the bag’s seal area. This controlled heat melts the thermoplastic layers, fusing the edges together securely. Activation only occurs when the heat bars are fully closed, ensuring safety and effective sealing. The typical sealing time is around three seconds, providing enough heat for a durable bond without damaging the bag. Different types of heat bars, such as impulse, constant, or bi-active, are used to optimize sealing for various materials and conditions. Proper heat bar design guarantees consistent, leak-proof seals that maintain vacuum integrity and extend shelf life. Understanding sealing techniques helps improve overall sealing performance and durability, and regular maintenance of the heat bars can prevent uneven sealing or malfunctions.

The Step-by-Step Vacuum Sealing Process

To start vacuum sealing, you’ll need to prepare your bag by cleaning, drying, and filling it properly, leaving space for a good seal. Next, position the bag correctly in the sealer and activate the vacuum function to remove all air efficiently. Ensuring the correct seal quality is crucial for maintaining freshness and preventing leaks. Additionally, using a properly prepared bag helps achieve optimal vacuum levels and prolongs the storage life. Finally, seal the bag securely and check for any leaks, ensuring your food stays fresh longer.

Preparing the Bag

Are you ready to prepare your bag for vacuum sealing? To guarantee a proper seal, start by thoroughly cooling your food to prevent condensation inside the bag. Remove excess moisture from food surfaces with paper towels or a clean cloth to reduce spoilage risks. Portion your food into manageable sizes for easier handling and storage. If sealing meat, choose fresh, high-quality cuts and consider seasoning or marinating beforehand for added flavor. Additionally, understanding food preservation techniques can help you organize your supplies more effectively. Finally, label and date each bag to keep track of freshness and organize your storage efficiently.

Removing Air Effectively

Ever wonder how to effectively remove air during vacuum sealing? First, place your food inside the bag, ensuring there’s enough space near the open edge for sealing. For moist foods, pre-freezing or drying helps improve air removal. Position the bag correctly based on your sealer type—chamber models require the whole bag inside, while edge sealers need precise alignment at the seal line. When you start the vacuum pump, it lowers the internal pressure, pulling the air out of the bag or chamber. Good pump strength and proper machine operation are essential for efficient air extraction. During this process, visually check for air pockets or bubbles, and perform a pull-test after sealing to confirm the seal’s integrity. Effective air removal prevents spoilage and extends shelf life. Additionally, understanding the effectiveness of vacuum pumps can help optimize your sealing results. Ensuring the correct sealing technique is crucial for maintaining a proper vacuum and preventing leaks.

Sealing and Finishing

Have you ever wondered how to achieve a perfect vacuum seal? The sealing and finishing step is vital. First, prepare your bag by selecting the right size and placing your item inside, leaving enough space for sealing. Confirm the open end is clean and properly aligned on the sealing platform. When ready, close the lid or lower the sealing arm to activate the heat bar, which melts the plastic to form an airtight seal. The process is controlled automatically or manually, depending on your machine. After sealing, wait for the heat bar to cool before opening to prevent damage. Remember to inspect the seal for continuity and strength. Properly sealing the heat bar ensures your food stays fresh and protected from air and moisture.

Maintaining and Troubleshooting Your Vacuum Sealer

Maintaining and troubleshooting your vacuum sealer is essential for ensuring it performs reliably and lasts longer. Daily, clean the exterior, sealing chamber, and seal groove with warm water and a neutral detergent to prevent residue buildup. Wipe the seal bar after each use with a damp cloth, avoiding harsh cleaners. Inspect and clean the vacuum chamber, seal bar, and gasket regularly to prevent debris from impairing sealing. Check the gasket for wear and replace it if damaged. Routinely examine electrical cords and connections for damage, and replace if necessary. Lubricate moving parts like sealing jaws with food-grade lubricant, and clean or replace the vacuum pump filter as recommended. Troubleshoot issues like uneven seals, jams, or vacuum leaks by adjusting settings, inspecting components, and replacing worn parts. Ensuring proper maintenance also involves understanding the regulatory standards governing electrical appliances to prevent safety hazards. Additionally, adhering to manufacturer-recommended maintenance schedules can help identify potential issues before they cause significant problems.

Practical Uses and Benefits of Vacuum Sealing

Vacuum sealing helps you keep food fresh longer, saving you money and reducing waste. It also frees up space in your fridge and freezer by compressing packages into compact, organized stacks. With these benefits, you can store more food efficiently while maintaining quality and flavor. Incorporating organized workspaces can further enhance your efficiency and reduce clutter during food storage and preparation. Additionally, understanding how vacuum pumps operate can help you troubleshoot and maintain your vacuum sealer for optimal performance.

Extends Food Shelf Life

Vacuum sealing dramatically extends the shelf life of your food by removing oxygen, which is a primary factor in spoilage. Without oxygen, bacterial growth, mold, and oxidation slow down considerably, keeping your food fresher longer. Research shows vacuum sealing can prolong shelf life up to five times compared to traditional storage. Foods like meats, cheeses, and vegetables benefit the most because they’re highly susceptible to air-induced spoilage. Here are some key benefits:

- Inhibits bacteria, mold, and spoilage organisms

- Reduces oxidation and nutrient loss

- Preserves flavor, aroma, and texture

- Prevents freezer burn and dehydration

- Extends usability before spoilage occurs

- Incorporating total‑cost clarity can enhance the performance of vacuum sealers for specialized needs.

This method helps you enjoy your food longer while maintaining safety and quality, reducing waste, and saving money.

Space Saving Benefits

By removing excess air and compressing contents, vacuum sealing substantially reduces the space needed for food and textiles. It shrinks textile volumes to about 20% or less of their original size by collapsing internal air pockets, maximizing storage efficiency. Food packages become more compact, allowing you to stack items tightly in refrigerators, freezers, or pantries. Unlike bulky boxes or chests, vacuum-sealed bags conform snugly around contents, eliminating wasted space. This compactness makes transporting and organizing items easier, especially in small living spaces or when traveling. Additionally, vacuum sealing creates uniform, space-efficient packages that optimize shelf and drawer storage. Proper wall organization can further enhance your storage efficiency by keeping items accessible and well-arranged. Incorporating storage solutions tailored to your needs can also help maintain an organized space and prevent clutter buildup. Overall, it allows you to save valuable space, keep your storage areas tidy, and make the most of limited storage capacity.

Frequently Asked Questions

How Long Does a Typical Vacuum Sealer Heat Bar Last Before Replacement?

A typical vacuum sealer heat bar lasts around 4,000 to 5,000 seal cycles before needing replacement. You should watch for signs like cracks, broken wires, or seal failures, which indicate it’s time to replace it. To extend its lifespan, use the lowest effective heat setting, handle it carefully, and perform regular maintenance. Keeping spare parts handy ensures you can maintain maximum sealing performance without delay.

Can Vacuum Pump Speed Be Adjusted for Different Sealing Needs?

Think of your vacuum pump as a musical instrument that can change its tune to suit your needs. You can adjust its speed with mechanisms like vee belt drives, fluid couplings, or pressure relief valves. This flexibility helps you fine-tune the evacuation process, whether you’re sealing delicate items softly or speeding up for quick batches. Proper adjustments ensure ideal sealing, efficiency, and equipment longevity, making your process smooth and reliable.

What Safety Precautions Should Be Taken During Vacuum Sealer Maintenance?

During vacuum sealer maintenance, you should always unplug the device first to prevent electrical shocks. Wear protective gloves and eye protection to avoid burns from hot surfaces or spilling liquids. Keep the area clean and well-ventilated, and inspect electrical cords and connections for damage. Follow manufacturer instructions carefully, especially when replacing parts like gaskets or heating elements. Regularly check and maintain oil levels and seals to guarantee safe, efficient operation.

Are There Specific Bag Types Compatible With All Heat Bars?

Not all bag types are compatible with every heat bar. Generally, polyethylene bags around 3 mil thick work well across most machines. FDA-approved, BPA-free bags tend to be broadly compatible, while specialty bags like foil or laminated films often require specific heat settings. Always check your vacuum sealer’s specifications and match the bag material to guarantee a proper seal, avoiding weak or failed seals.

How Does Ambient Temperature Affect Vacuum Sealing Efficiency?

Ambient temperature is like the weather’s mood, shaping your sealing process. When it’s too hot, your heat bars risk overheating, making seals brittle or weak. Cold conditions can slow down heat transfer, causing incomplete seals. You’ll find that adjusting your settings based on temperature helps maintain efficiency, guaranteeing your vacuum pump works smoothly without strain. Keeping a consistent environment, or adapting to it, ensures your seals stay airtight and reliable.

Conclusion

Understanding how heat bars and vacuum pumps work helps you get the most out of your vacuum sealer. Think of it like tuning a musical instrument—you’ll produce a perfect seal every time. With a little practice, you’ll preserve your food better and save money, just like a skilled chef perfects their craft. Once you grasp these components, sealing becomes second nature, keeping your food fresh and your kitchen organized.