Nanotechnology coatings for anti-fingerprint surfaces use nanoscale materials to create thin, durable layers that repel oils, dirt, and smudges. These coatings reduce surface energy and create micro-roughness, making fingerprints easier to wipe away while maintaining clarity and gloss. They also add scratch resistance and water repellency, prolonging device life. By applying proper techniques and maintenance, you can keep surfaces cleaner longer. To discover the latest innovations and safety tips, keep exploring further.

Key Takeaways

- Nanotechnology coatings create ultra-thin, uniform layers that reduce surface energy, preventing fingerprint oils from adhering effectively.

- These coatings incorporate nanostructures that disperse light and repel oils, maintaining surface clarity and cleanliness.

- Proper surface preparation and application techniques ensure durable, high-quality anti-fingerprint nanocoatings on glass and metal surfaces.

- Hydrophobic properties of nanocoatings cause water and oils to bead and roll off, minimizing fingerprint visibility and smudges.

- Advances in nanotech enable multifunctional coatings with self-cleaning, anti-scratch, and fingerprint-resistant features for electronic devices.

How Nanotechnology Enhances Surface Properties

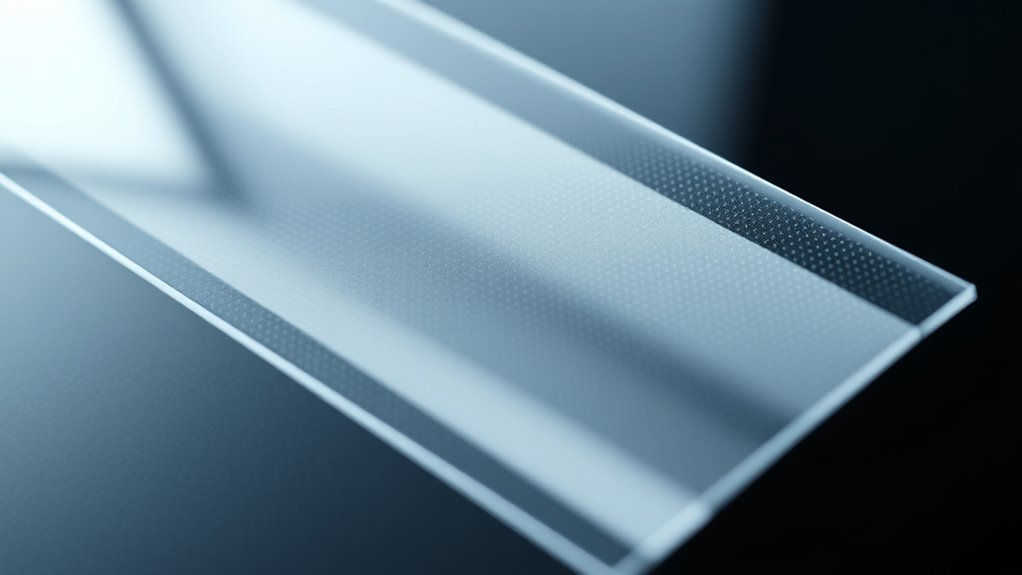

Nanotechnology substantially improves surface properties by manipulating materials at the atomic and molecular levels. When you apply nanocoatings, you’re fundamentally creating a thin, uniform layer that alters how surfaces interact with their environment. This layer can make surfaces more resistant to scratches, corrosion, and dirt buildup, keeping them cleaner longer. Nanoparticles fill in microscopic imperfections, enhancing durability and reducing wear. Additionally, these coatings can change surface energy, making them hydrophobic or oleophobic, which means water and oils bead up and roll off instead of sticking. As a result, surfaces remain cleaner and easier to maintain. The use of nanoparticles in coatings further enhances their ability to provide long-lasting protection and performance. Moreover, nanotechnology allows for precise material control, enabling the customization of surface properties for specific applications. This control also enables the development of multi-functional coatings that combine several protective features into a single layer. With nanotechnology, you’re not just improving appearance but also extending the lifespan and functionality of various materials, all by fine-tuning their atomic and molecular structures. Advances in surface energy modification help in tailoring coatings for specialized environments and uses. Furthermore, recent innovations in self-cleaning surfaces utilize nanotech to actively break down dirt and repel contaminants, enhancing maintenance ease.

The Science Behind Anti-Fingerprint Coatings

Anti-fingerprint coatings utilize nanotechnology to address one of the most common surface issues: fingerprints and smudges. These coatings are made from nanoscale materials that create a protective layer on surfaces like glass and metal. This layer reduces the surface energy, making it difficult for oils and dirt from your fingers to adhere. The nanostructures create a rough, yet smooth, surface that minimizes the appearance of fingerprints by dispersing light and preventing smudges from sticking. Additionally, some coatings incorporate hydrophobic properties, causing water and oils to bead up and roll off easily. The science behind anti-fingerprint coatings combines surface chemistry and nanostructures to keep surfaces cleaner, clearer, and less prone to visible marks, maintaining your device’s pristine appearance longer. Moreover, understanding the role of contrast ratio in image quality can help in choosing surfaces that enhance visual clarity and overall display performance. These innovative coatings leverage surface chemistry to optimize both functionality and aesthetics.

Benefits of Nanotech Coatings on Electronic Devices

Applying nanotech coatings to electronic devices offers numerous advantages that enhance both their performance and longevity. These coatings provide superior scratch resistance, keeping screens and surfaces looking new longer. They also repel oils and fingerprints, reducing cleaning frequency and improving user experience. Additionally, nanocoatings enhance water and dust resistance, safeguarding electronics in various environments. This protection minimizes damage and extends device lifespan. Furthermore, nanotech coatings can improve device aesthetics by maintaining clarity and glossiness over time. Durability is further increased as these coatings help resist environmental wear and tear. Moreover, the self-cleaning properties of nanocoatings can reduce the need for frequent cleaning, saving time and effort. Below is a table highlighting key benefits:

| Benefit | Description | Impact |

|---|---|---|

| Scratch Resistance | Hard nanostructures protect surfaces | Longer-lasting screens |

| Oil & Fingerprint Resistance | Reduces smudges and grime | Easier cleaning |

| Water/Dust Resistance | Prevents moisture and debris ingress | Increased durability |

| Enhanced Clarity | Maintains display visibility over time | Better user experience |

| Longevity | Reduces wear and tear | Cost-effective investment |

Application Processes for Nano-Engineered Films

To guarantee the best results, you need to start with proper surface preparation techniques that promote adhesion. Next, choose the right coating application method, whether it’s spraying, dipping, or spin-coating, to achieve uniform coverage. Proper surface cleaning can remove contaminants that might compromise the adhesion of the nano-engineered film. Additionally, selecting the appropriate surface treatment can further enhance coating performance. Incorporating sound vibrations during curing processes has been shown to improve coating uniformity and strength. Moreover, employing remote collaboration tools can facilitate team coordination during complex application procedures, especially for distributed teams. Finally, curing processes and quality control checks are essential to guarantee the film’s performance and durability. Consulting retail hours can help ensure timely application by scheduling around store availability for supplies and services.

Surface Preparation Techniques

Preparing surfaces properly is essential for guaranteeing the effective adhesion and performance of nano-engineered coatings. You need a clean, smooth, and chemically compatible surface to maximize coating durability. Start by removing dirt, oils, and residues through thorough cleaning methods like solvent wiping or ultrasonic cleaning. Surface roughening, such as light abrasion or plasma treatment, enhances mechanical bonding. Sometimes, applying a primer or adhesion promoter improves compatibility between the substrate and the nano-coating. Proper surface preparation minimizes defects and ensures uniform coating application.

- Cleaning methods: solvent wiping, ultrasonic cleaning

- Surface roughening: abrasion, plasma treatment

- Adhesion promotion: primers, adhesion promoters

Coating Application Methods

Once the surface has been properly prepared, selecting the appropriate application method guarantees the nano-engineered coating forms a uniform, durable film. You can apply these coatings through spray, spin coating, dip coating, or roll coating, depending on the substrate’s size and shape. Spray coating is versatile and ideal for large or complex surfaces, allowing for even coverage with minimal waste. Spin coating suits flat, small surfaces, creating a thin, uniform layer quickly. Dip coating involves immersing the object into the coating solution, ensuring thorough coverage, especially for intricate geometries. Roll coating is efficient for continuous production lines and large surfaces, providing consistent film thickness. Choose the method that best matches your surface characteristics and production needs to ensure superior coating performance. Additionally, understanding the application methods is crucial for achieving a consistent and durable nano-engineered film, as proper technique impacts the coating’s adhesion and longevity. Incorporating growing industry trends can further optimize coating processes and outcomes, making sure the application aligns with current advancements in resources and tools for better results.

Curing and Quality Control

After applying the nano-engineered coating, proper curing and thorough quality control are essential to guarantee ideal performance and durability. Proper curing ensures the coating forms a strong, uniform layer that bonds effectively to the substrate. It often involves controlled temperature, humidity, or UV exposure, depending on the material. Once cured, conduct quality control to verify coating integrity, adhesion, and evenness. This step helps identify defects like pinholes, cracks, or uneven coverage before the product reaches users. Regular inspection and testing are crucial to maintain high standards. By ensuring proper curing and quality control, you maximize the coating’s anti-fingerprint performance and longevity.

- Verify curing parameters and completion

- Conduct adhesion and durability tests

- Inspect for surface defects and uniformity

Durability and Maintenance of Nano Coatings

Nano coatings are designed to be highly durable, but their longevity depends on proper maintenance and environmental conditions. To preserve their anti-fingerprint properties, you should clean surfaces regularly with mild detergents and avoid abrasive cleaners that can damage the coating. Environmental factors like extreme heat, UV exposure, or harsh chemicals can degrade the coating over time. Proper maintenance ensures the coating’s effectiveness and prolongs its lifespan.

| Maintenance Tip | Effectiveness |

|---|---|

| Use soft, non-abrasive cloth | Prevents scratches and damage |

| Avoid harsh chemicals | Preserves coating integrity |

| Regular cleaning | Maintains anti-fingerprint properties |

Future Developments in Nanotechnology for Surface Protection

Advancements in nanotechnology are paving the way for increasingly sophisticated surface protection solutions. You can expect future coatings to offer enhanced self-healing capabilities, automatically repairing minor damages to maintain their protective properties. Researchers are also developing multifunctional coatings that combine anti-fingerprint features with antimicrobial or UV-blocking functions, giving you more versatile options. Additionally, innovations in scalable manufacturing processes will make these advanced coatings more affordable and accessible. These developments will lead to longer-lasting, more durable surfaces that reduce maintenance needs and improve user experience. As nanotechnology continues to evolve, you’ll benefit from smarter, more efficient protective coatings that adapt to your environment and usage patterns. Staying informed about these trends helps you anticipate future improvements and select the best solutions for your needs.

Environmental Impact and Safety Considerations

As nanotechnology coatings become more widespread, it’s crucial to take into account their environmental and safety impacts. You should be aware that some nanomaterials may pose risks to ecosystems and human health if not properly managed. During production, disposal, or wear, nanoparticles can be released into air, water, or soil, potentially causing toxicity. Regulations are still evolving, so it’s important to stay informed about safety standards and best practices. You can minimize risks by choosing eco-friendly nanomaterials and implementing proper handling procedures. Additionally, conducting thorough life-cycle assessments helps identify potential hazards early. By prioritizing safety and environmental considerations, you ensure that nanotechnology coatings benefit society without unintended harm.

Frequently Asked Questions

How Do Nano Coatings Affect Touchscreen Sensitivity?

You might wonder how nano coatings impact touchscreen sensitivity. These ultra-thin layers don’t add bulk or interfere with touch signals. Instead, they enhance durability and repel fingerprints without compromising responsiveness. When applied correctly, nano coatings allow your finger to glide smoothly, maintaining quick and accurate interactions. So, you can enjoy a fingerprint-free surface without sacrificing the ease of use or sensitivity of your touchscreen device.

Are Nano Anti-Fingerprint Coatings Safe for Human Contact?

Imagine touching a smooth, spotless surface that feels safe and clean every time. You might wonder if nano anti-fingerprint coatings are safe for your skin. Rest assured, these coatings undergo rigorous testing to guarantee they’re non-toxic and biocompatible. They’re designed to be gentle, so you can confidently use your devices without worry, knowing that your skin stays protected and contact remains safe and seamless.

Can Nano Coatings Be Removed or Replaced Easily?

You might wonder if nano coatings can be removed or replaced easily. Generally, these coatings are designed to be durable, but they can often be eliminated with specific cleaning agents or abrasives if needed. Replacing them usually involves reapplying the coating, which can be straightforward depending on the surface. However, it’s best to follow manufacturer instructions for removal and reapplication to ensure effectiveness and avoid damage.

What Are the Costs Associated With Nano Coating Applications?

You’re wondering about the costs involved in applying nano coatings. The expenses vary depending on the surface size, type of coating, and application method. Typically, you’ll pay for the material, labor, and equipment used. While nano coatings can be more expensive upfront than traditional treatments, their durability and protective benefits often justify the investment. You should get quotes from suppliers to understand the specific costs for your project.

How Do Nano Coatings Perform Under Extreme Environmental Conditions?

Did you know that nano coatings can withstand temperatures up to 1,200°C? When it comes to extreme environments, these coatings perform remarkably well, providing excellent resistance to corrosion, UV radiation, and abrasion. You’ll find them durable in harsh conditions like industrial settings or outdoor applications. Their ability to maintain protective qualities under such stress makes them a reliable choice for ensuring longevity and performance in challenging environments.

Conclusion

By embracing nanotechnology, you enhance surface durability, reduce fingerprints, and enjoy a sleek, clean look. You benefit from advanced protection, effortless maintenance, and longer-lasting devices. You explore innovative applications, stay ahead with future developments, and prioritize safety and environmental care. Ultimately, nanotech coatings transform your experience—making surfaces smarter, cleaner, and more resilient—empowering you to enjoy technology that’s built to perform, built to last, and built with care.