Choosing between air-cooled and water-cooled machines depends on your needs. If you want a simple setup with lower upfront costs and easier maintenance, air cooling is likely best, especially for moderate workloads. But if you often run heavy tasks or prefer better heat management to boost performance and longevity, water cooling is more suitable, despite its complexity. To find out which suits your environment and budget, explore the detailed differences below.

Key Takeaways

- Water-cooled systems offer higher thermal efficiency and better heat management for high-demand or continuous operations.

- Air-cooled machines are simpler, cheaper initially, and require less maintenance, suitable for moderate workloads and limited spaces.

- Hot climates and intensive performance needs favor water cooling, while cooler environments may suffice with air cooling.

- Water cooling involves regular maintenance like leaks checks and coolant replacement, whereas air cooling is more straightforward.

- Consider long-term performance and operational costs: water cooling can be more expensive upfront but may reduce downtime and extend machine lifespan.

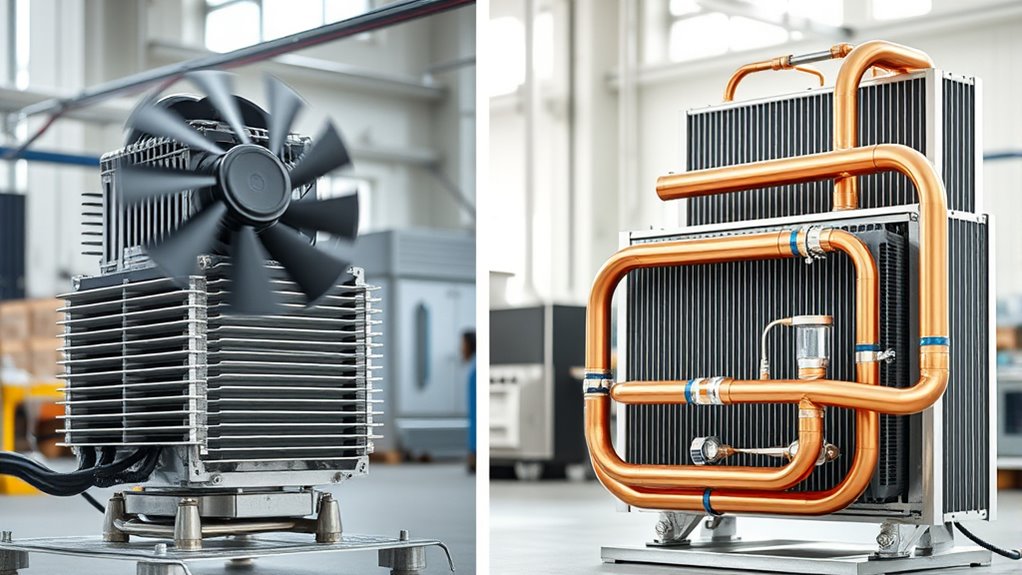

When choosing between air-cooled and water-cooled machines, understanding how each system manages heat is vital. Your decision can markedly impact the machine’s thermal efficiency, overall performance, and ongoing maintenance needs. Air-cooled systems use fans and fins to dissipate heat directly into the surrounding air. They are straightforward, often more compact, and require less initial setup, making them convenient for many applications. However, because air doesn’t transfer heat as efficiently as water, these systems tend to have lower thermal efficiency, especially under heavy workloads or in hot environments. This means your machine might run hotter and, over time, could experience reduced performance or increased wear if not properly managed.

Air-cooled systems are simpler and more compact but less efficient under heavy workloads or hot environments.

On the other hand, water-cooled systems employ a liquid coolant that circulates through the machine, absorbing heat more effectively. This allows for better thermal management, often leading to higher thermal efficiency, especially in demanding or continuous-use scenarios. The coolant’s ability to carry heat away more efficiently means your machine can operate at ideal temperatures for longer periods, potentially extending its lifespan and maintaining consistent performance. Additionally, water-cooled systems are often used in high-performance applications, where optimal temperature control is critical. However, water-cooled systems come with more complex maintenance requirements. They need regular checks for leaks, coolant levels, and quality, as well as periodic flushing and replacement to prevent corrosion and buildup. If neglected, these issues can lead to costly repairs and downtime.

Your environment and usage patterns play a vital role in choosing the right system. If you operate in a setting with moderate workloads and limited space, an air-cooled machine might be sufficient, offering easier upkeep and fewer technical concerns. Conversely, if your operations demand high performance, extended run times, or operate in hot climates, a water-cooled system’s superior heat management becomes advantageous, justifying the additional maintenance efforts. Additionally, modern heat pumps with noise reduction technology can operate quietly in either system, making them suitable for various environments.

Cost is another factor to weigh. Air-cooled machines often have lower upfront costs and simpler designs, making them more affordable initially. Water-cooled systems, while pricier to install and maintain, can deliver better long-term performance and efficiency, which might offset the initial investment over time. Ultimately, your choice hinges on balancing your performance needs, budget, and willingness to handle maintenance tasks. By understanding how each system manages heat, you can select a machine that aligns with your operational goals, ensuring reliability and efficiency without unnecessary complications.

Frequently Asked Questions

Which Cooling System Is More Environmentally Friendly?

When considering which cooling system is more environmentally friendly, you should look at their environmental impact and sustainability. Air-cooled systems generally have a lower environmental footprint because they don’t require water, reducing water consumption and potential pollution. Water-cooled systems can be more efficient but may use more resources and produce wastewater. So, if environmental impact and sustainability matter most, air-cooled options often come out ahead.

How Does Maintenance Differ Between Air and Water Cooling?

Ever wondered how maintenance differs between cooling systems? With air cooling, you’ll mainly clean vents and fans to maintain thermal efficiency, boosting component longevity. Water cooling, however, demands checking for leaks, coolant levels, and potential corrosion, which can be more complex. The suspense lies in how each system’s upkeep impacts your machine’s performance over time. Choose wisely, knowing that maintenance intensity directly influences thermal efficiency and the lifespan of your components.

Can Water-Cooled Systems Operate Outdoors Effectively?

Water-cooled systems can operate outdoors effectively if you guarantee they have proper weather resistance and outdoor durability. You should protect components from rain, snow, and extreme temperatures with suitable enclosures and corrosion-resistant materials. Regular maintenance helps prevent leaks and corrosion, ensuring reliable performance. While water-cooled units need more protection than air-cooled ones, with proper setup, they can handle outdoor environments and deliver efficient cooling.

Are There Cost Differences Over the Machine’S Lifespan?

Think of costs like a garden—you need to tend it wisely. Water-cooled machines often have higher initial installation costs but tend to save you money on long-term expenses through better efficiency and durability. Air-cooled systems generally cost less upfront but might incur higher maintenance and energy costs over time. So, consider both your immediate budget and future savings to choose the best option for your needs.

Which Cooling Method Offers Better Noise Reduction?

When it comes to noise levels, water-cooled machines typically offer better sound insulation, reducing noise markedly during operation. You’ll notice quieter performance because water cooling keeps components cooler and operates more smoothly, minimizing vibrations and sound. If low noise is a priority for you, water-cooled systems can provide a more peaceful environment, especially in noise-sensitive settings, making them a smart choice for reducing overall sound insulation needs.

Conclusion

Choosing between air-cooled and water-cooled machines is like picking a vehicle: one offers simplicity and reliability, while the other provides powerful performance with a touch of complexity. I once watched a friend struggle with overheating his water-cooled rig during a critical project, reminding me that sometimes, less is more. Ultimately, consider your needs and environment. Like a well-chosen car, the right cooling system keeps you running smoothly without unnecessary fuss.