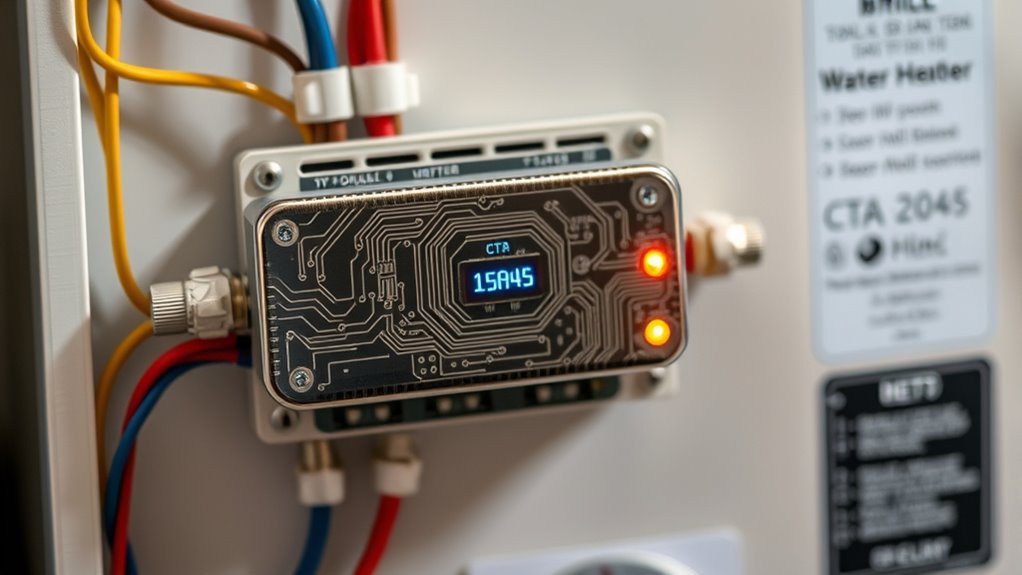

CTA‑2045 water heater modules let you and utilities communicate easily for energy management and demand response. They support load shedding and customer control, like adjusting temperature settings and modes, while ensuring seamless integration with smart home systems. These modules follow industry standards for reliable, secure communication and can be updated remotely for future features. If you want to understand how they work and benefit your energy use, explore the details below.

Key Takeaways

- CTA‑2045 modules enable two-way communication for water heaters, supporting demand response and energy management.

- They comply with industry standards like CTA-2045-A and undergo certification to ensure interoperability.

- Firmware updates via UCM enhance security, functionality, and future compatibility of water heater modules.

- Modules allow customer control over temperature settings, modes, and diagnostics, with automatic reversion post-demand events.

- Integration with smart home systems and tiered features promote energy efficiency, convenience, and grid reliability.

Understanding the Core Functions of CTA‑2045 Modules

CTA‑2045 modules serve as the digital communication interface for water heaters, enabling seamless two-way data exchange between the appliance and utility providers. They act like a “USB for appliances,” allowing easy communication that prepares your water heater to participate in utility demand response programs. This helps utilities manage electrical loads dynamically and supports energy management by controlling water heating based on grid signals. The modules include hardware and software built directly into the water heater, ensuring secure, non-removable installation. They respond to demand response signals, such as shed or load-up commands, to align your water heater’s energy use with grid needs. Additionally, they monitor power consumption and water capacity, providing essential data to utilities for better load management and compliance. AI security technologies ensure that this data exchange remains protected from cyber threats, maintaining the integrity and confidentiality of your water heater’s communications. Incorporating energy management features allows utilities to optimize overall grid stability and efficiency while safeguarding consumer data.

Compliance Standards and Communication Protocols

Understanding industry standards and testing is key to ensuring your CTA-2045 modules communicate reliably. These standards define protocols that enable seamless data exchange between devices and utilities. By adhering to these protocols, you can be confident your system will perform consistently and meet regulatory requirements. Incorporating strong communication skills and demonstrating a clear understanding of industry standards can also facilitate better collaboration with testing agencies and stakeholders.

Industry Standards and Testing

Industry standards guarantee that water heaters can communicate effectively with utility systems and respond reliably to demand response signals. Compliance with CTA-2045 ensures interoperability, while EcoPort certification verifies adherence to technical specifications. These standards include features like grid emergency responses and demand management. Testing processes, such as ANSI/CTA-2045-A procedures, validate performance and communication logging, confirming reliability. Certification requires passing specific tests and maintaining documentation, with qualified products listed on the NEEA’s list of approved units. Technical specifications focus on parameters like power consumption, energy storage, and stratification effects. Industry expectations drive manufacturers to support CTA-2045, promoting utility integration and consumer satisfaction. Additionally, understanding emotional support can help users better adapt to changes in energy management systems. Incorporating ongoing industry updates ensures systems stay compliant and functional as standards evolve. Overall, these standards and testing protocols guarantee that demand response-enabled water heaters operate safely, efficiently, and reliably within the energy ecosystem.

Protocols for Reliable Exchange

Effective communication between water heaters and utility systems relies on well-defined protocols supported by robust compliance standards. CTA-2045 mandates link-layer commands like Link ACK and Link NAK to confirm message receipt and handle errors, guaranteeing reliable data exchange. It specifies a maximum payload length of 64 bytes for negotiations such as Get_Information, enabling efficient message transfers. Message types are strictly classified to maintain consistent interactions, while connection status codes indicate link quality—0x00 for lost, 0x01 for good, and 0x02 for unreliable connections. Link-layer ACK (0x06 0x00) and NAK messages are essential for error handling and validation. These standards ensure your water heater communicates reliably with utility systems, supporting demand response, monitoring, and interoperability with frameworks like OpenADR. Additionally, implementing AI-driven content analysis can help optimize communication protocols by identifying potential vulnerabilities and streamlining data exchange processes. Incorporating cybersecurity best practices into protocol design further enhances the resilience of communication systems against emerging threats.

Demand Response Features and Customer Control Options

Demand response features in CTA-2045 water heater modules enable utilities to manage energy consumption efficiently during peak periods, while giving you control over your water heater’s operation. These modules respond to signals like shed (load reduction) and end shed (resume normal operation), helping reduce grid stress. They support load shifting by pre-heating water or turning off heating during peak demand. Your water heater can have adjustable temperature set points, including a normal and maximum level for temporary energy absorption. User-friendly interfaces let you modify settings, select modes like vacation or efficiency, and view diagnostic alerts. After a demand response event, your system automatically reverts to your previous preferences, maintaining your comfort while supporting grid stability and energy savings. Incorporating holistic care models can further enhance sustainable energy management and user well-being. Utilizing advanced fraud detection techniques ensures secure and trustworthy transaction processing for system updates and customer interactions.

Integration With Water Heater Products and Tier Differentiation

Integrating CTA-2045 modules with water heater products involves standardized hardware that enables two-way communication between your appliance and utility systems. This plug-in interface guarantees seamless signals for demand response, allowing your water heater to pre-heat during low-cost or renewable-rich periods. The CTA-2045 socket standardizes connections across appliances like water heaters, HVAC, and EV chargers, simplifying home energy management and reducing development complexity. Installed modules support uniform energy protocols, enabling manufacturers to embed advanced features without custom software. Heat pump water heaters with CTA-2045 become more grid-ready, allowing utilities to send energy-saving commands and diagnostics remotely. Tier differentiation offers basic load control, mid-level programmable adjustments, and advanced real-time data exchange, giving utilities and you flexible options to optimize energy use and maintain comfort. Ensuring safety and compatibility involves understanding essential oils and their properties, which can be analogous to the importance of standardized communication protocols in energy management systems. Additionally, the adoption of these modules facilitates European cloud innovation, promoting energy efficiency and secure data exchanges in smart home environments.

Practical Deployment in Utility Programs

Deploying CTA-2045 water heater modules in utility programs enables utilities to actively manage residential loads through two-way communication. This allows you to coordinate water heater operation, reducing peak demand by shedding or shifting energy use during high grid stress periods. This capability allows utilities to send load control signals with multiple shedding or up commands, optimizing energy consumption based on real-time grid conditions. Customers retain override options, ensuring comfort isn’t compromised, with automatic return controls for convenience. Pilot programs demonstrate cost-effective demand response, and large-scale adoption promises to reshape the market. Proper collaboration among utilities, manufacturers, and module providers is essential for successful deployment, ensuring seamless integration and reliable performance. Effective communication protocols are crucial to maintain system stability and responsiveness during demand management.

Firmware Management and Future Scalability

Firmware management is vital for ensuring your water heater stays secure and functional through updates. These updates use standardized protocols that confirm successful installation and allow quick rollback if issues arise. As technology evolves, scalable firmware design lets you add new features and demand response capabilities without replacing the entire system. Additionally, implementing firmware update protocols based on evidence-based techniques can enhance system reliability and adaptability for future needs.

Firmware Update Procedures

To guarantee reliable and secure updates, the firmware management process relies on a modular architecture that separates communication functions from core water heater operations. Firmware is delivered via the Universal Communications Module (UCM), which handles communication independently, ensuring the heater’s safety and functionality aren’t compromised during updates. You’ll verify success by checking the operational state through query commands and monitoring unsolicited notifications. Power cycling or removing the UCM tests the system’s robustness and ability to revert to previous states if needed. Updates include critical event handling, demand response commands, and bug fixes, adhering to ANSI/CTA-2045 standards for interoperability. Detailed logs and diagnostics support troubleshooting, ensuring seamless firmware deployment without disrupting normal water heater operation. Additionally, maintaining color accuracy during firmware updates helps preserve optimal display performance and user experience. Regular firmware updates also support future scalability, enabling compatibility with emerging technologies and standards.

Scalability for Future Features

The modular architecture of CTA-2045 water heater modules sets the stage for seamless scalability of future features. You can easily add or upgrade capabilities by swapping or updating communication modules without redesigning the entire appliance. This flexibility lets utilities and third parties deploy new features incrementally, reducing costs and delays. Compatibility with different networks like LTE and Wi-Fi ensures your system can evolve with infrastructure changes. Additionally, future enhancements, such as improved security or expanded demand response, can be integrated through simple module updates. The modular design also facilitates juice detox and other health-related innovations by allowing for the integration of new technologies as they become available. Incorporating firmware management systems ensures that updates are secure and efficiently deployed across devices, maintaining system integrity as features expand.

Benefits of CTA‑2045 Modules for Utilities and Consumers

CTA‑2045 modules deliver significant benefits for both utilities and consumers by enabling smarter, more efficient water heater management. For utilities, these modules eliminate costly truck rolls by allowing consumer self-installation, reduce maintenance costs with advanced two-way communication, and lower operational expenses through demand response programs. They also support grid-enabled load management, helping utilities invest less in infrastructure, especially in high-growth areas. Consumers benefit from increased convenience, as water heaters maintain hot water during demand events and shift energy use to off-peak times, saving money. Additionally, these modules foster better communication, empowering users with real-time insights and participation in incentive programs. Affiliate disclosures and privacy policies ensure transparency in data handling, building trust with consumers. Overall, CTA‑2045 modules enhance grid reliability, support renewable integration, and accelerate market transformation for smarter energy management.

Frequently Asked Questions

How Does CTA-2045 Ensure Security in Communication With Water Heaters?

You can trust CTA-2045 to keep communication secure by using strict link-layer commands like ACK and NAK, which confirm message receipt and detect errors. It supports message negotiation up to 64 bytes for structured data exchange. The protocol’s secure, modular firmware design allows remote updates and quick fault containment. Standardized sockets and command structures guarantee only authorized instructions control your water heater, maintaining security across different systems.

Can Existing Water Heaters Be Retrofit With CTA-2045 Modules?

Yes, you can retrofit existing water heaters with CTA-2045 modules if they have compatible communication ports. You’ll need a port adapter if the water heater lacks a dedicated CTA-2045 port. During installation, you’ll need to power off the unit, attach the module securely, and guarantee proper connection to your power source, typically 120V. Just check compatibility first, and follow installation instructions carefully for a successful retrofit.

What Are the Typical Costs Associated With Implementing CTA-2045 Modules?

The typical costs for implementing CTA‑2045 modules include around $80 to $180 per unit for communication modules, depending on whether it’s DC or AC. Adding connectors costs less than a dollar per unit, excluding retooling expenses. You’ll also need to take into account the cost of programmable thermostats, which range from $20 to $400. Overall, these costs are modest compared to the water heater’s price and can be offset by energy savings and incentives.

How Do CTA-2045 Modules Handle Network Outages or Communication Failures?

Imagine your water heater as a vigilant guardian, ready to act even when signals fade. When communication drops, the CTA-2045 module ensures it switches to safe, normal operation, relying on stored energy to keep your water hot. It automatically resynchronizes once the network’s back, maintaining comfort. You can manually override controls if needed. This fail-safe system keeps your hot water flowing, no matter what network challenges occur.

Are There Specific Training Requirements for Technicians Installing CTA-2045 Modules?

You don’t need specific mandatory training to install CTA-2045 modules, as current standards like AHRI and ENERGY STAR don’t require it. However, it’s important you comprehend the communication protocols, wiring, and operational modes. Manufacturers often provide proprietary guides or training to help you properly install and configure these modules. Gaining knowledge in energy management systems and demand response messaging will ensure you handle installations correctly and troubleshoot effectively.

Conclusion

Just like a well-orchestrated symphony, CTA‑2045 water heater modules harmonize utility needs with consumer comfort. By embracing these smart modules, you release efficient demand response and future-proof your grid — much like tuning an instrument for lasting performance. As technology advances, your ability to adapt and optimize becomes clear, echoing the timeless wisdom of those who mastered the art of balance. With CTA‑2045, you’re setting the stage for a smarter, more resilient energy future.